Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

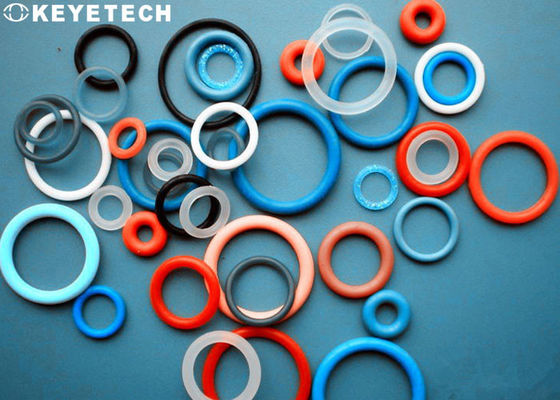

Product background

In the remanufacturing industry, due to the low unit price and large output of some products such as plastic, silicone rubber, hardware, etc., the defects of products such as scratches, cracks and fractures are not good. For example, sealing rings are important components in the fields of automobiles, electronics, semiconductors, and communications. important application. The traditional manual inspection is carried out by human eyes. Secondly, the cost is very high. Thirdly, quality problems such as missed mixtures are prone to occur.

Assuming that the sampling method is adopted for some products, the quality of the products cannot be guaranteed. At present, the application of machine vision in China has become very extensive, and intelligent manufacturing 4.0 is the most widely used. Some heavy industrial enterprises such as medicine, food, automobile, etc. used automated machine vision inspection equipment at the earliest stage. Today, I will explain several benefits of manual inspection in the machine age. , high efficiency, high precision, non-contact detection, etc.

Inspection principle&system configurations

The materials are arranged by vibrating plate, Linear vibration and non-destructive conveying, and the capacitance is stably and orderly transferred to the specific inspection station, and then the high-pixel sample image captured by the industrial camera is transferred to the image processing software. After the system analyzes and processes, it judges good and defective products, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products.

The inspection machine adopts high-pixel industrial cameras and high-performance stroboscopic light sources to carry out omni-directional visual inspections for product appearance defects. The inspection speed is 200-300 pieces/min. The equipment can realize 7*24 hours of all-weather operation, and it can be online automatically. Eliminate substandard products.

| Description |

Model |

Unit |

Q’ty |

Remark |

| Industrial Cameras |

KeyeTech |

Set |

6 |

China |

| Lenses |

KeyeTech |

Set |

6 |

China |

| LED Light Source |

KeyeTech |

Set |

3 |

China |

| Photoelectric Sensor |

SICK |

Pair |

1 |

Germany |

| Electromagnetic Valve |

SMC |

PC |

1 |

Japan |

| Industry Power |

Mean Well |

Set |

3 |

China |

| Main Control Board |

KeyeTech |

PC |

1 |

China |

| AI Computing Unit |

KeyeTech |

Set |

2 |

China |

| Pollution Filter |

KeyeTech |

Set |

1 |

China |

| HID Touch Screen |

AOC 21’ |

Set |

1 |

China |

| AI Algorithm System |

KeyeTech |

Set |

1 |

China |

| AI Cloud Platform |

KeyeTech |

Set |

1 |

China |

| Big Data Server |

KeyeTech |

Set |

1 |

China |

| Operation System |

Linux |

Set |

1 |

Finland |

After-sale service

he company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!