28mm PCO 1810 Bottle Cap Visual Inspection Machine Online Defect Sorting System

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Detection Standards

The traditional manual testing method has been difficult to meet the testing needs of the bottle cap production process in beverage and pharmaceutical industries. Quality control is the core competitiveness of modern manufacturers. To guarantee high-quality products, modern intelligent detection equipment is indispensable. The introduction of automatic bottle cap visual detection machine is a necessary choice in bottle cap production and detection, and also a long-term way to win the market.

|

Model

|

Camera number |

Detection range |

Detection content and accuracy |

Detection precision |

Accuracy of detection |

Detection speed |

| KVIS-CC06 |

4 sets

|

Outside part |

Black spots≥0.2mm |

99.9% |

99.9% |

500 pcs/min |

| 0.5mm<overlap and lack of material≤1mm |

99.9% |

|

1 set

|

Concave part |

0.5m<Lack of material ≤1mm |

99.9% |

| Black spots ≥0.2mm |

99.9% |

| 2mm<Deformed |

99.9% |

|

1 set

|

Trademark part |

Black spots ≥0.2mm |

99.9% |

| Note: This equipment adopts 2 million pixel level industrial cameras. |

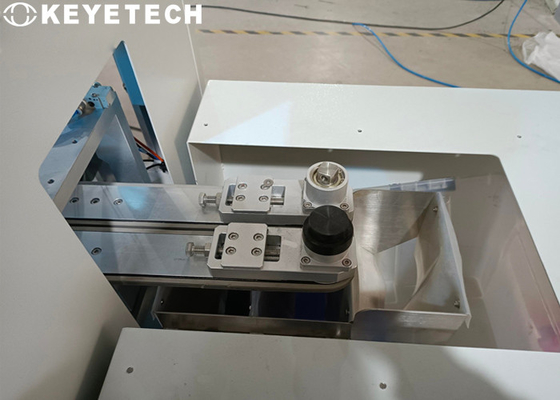

Detection details

The design plan for our company is equipped with industrial cameras, a cap organize machine to realize a full range of defect detection on the concave, trademark and side of the bottle caps. The normal detection speed is 500 pieces per minute; The front part of the detection machine can be equipped with a set of organize conveying equipment, to pour the caps into the cap organize machine, and transport them stably and orderly through the cap organize machine conveyor line through the industrial camera photographing area, and transfer the high-pixel sample image to the image processing software, to compare and analyze with the standardized model to determine the concave surface of the bottle cap and the trademark surface, whether there are unqualified products on the side, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products. the counting function can be performed after detecting the finished product, and the counting accuracy is over 99%. The equipment can operate for a full day of 7 x 24 hours.

Cooperation Partners

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G, Unilever, ALPLA, Shriji Polymer, Berry Global, Aptar, LAMIPAK, TPAC, PACT Group, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!