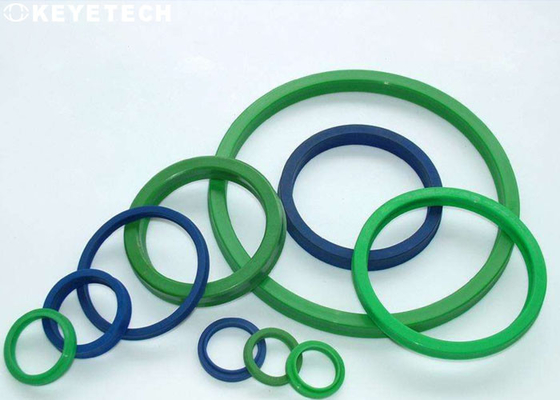

400pcs/Min Auto Visualizer Quality Inspection Machine For Sealing Rubber Ring

Features of system

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

In the past, all sealing ring inspections relied on manual labor, and manual quality inspection could only perform inspection and screening one by one. This inspection equipment uses machine vision inspection technology to screen out good and defective products through image processing. It is characterized by high inspection efficiency, fast inspection speed, and good quality inspection objectivity and stability. Manual quality inspection is more affected by subjective factors, but also by human emotions and senses, while the equipment will not. It can objectively and accurately detect the appearance and size of products and can inspection products in a high-efficiency and multi-dimensional manner.

Machine vision inspection equipment can detect defects such as burrs,flash, and cracks. Moreover, the detection accuracy is smaller than that of the human eye, and the defective products can be screened out more accurately. The system development is mainly aimed at the automatic inspection and automatic screening of defective products for rubber parts. The content of the inspection and screening includes:

a) mixed products.

b) Lack of material on both ends;

c) Defects such as burrs and burrs on the parting surface;

d) Additional size inspection items are required by the customer.

System Features:

1. The detection speed is 120~400pcs or more per minute;

2. Repeated detection accuracy of projection size: within ±0.005mm (defined as the camera's field of view within 10mm*10mm, unless otherwise specified)

3. Description of main accessories:

1) Camera: Hikvision;

2) Sensor: Japan OMRON;

3) Solenoid valve: original American brand;

4) PLC: Japan's Mitsubishi high-speed series.

4. HMI, the software comes with a toolbox, a convenient Microsoft Windows operating system developed for ordinary employees;

5. Production data report statistics function: automatic generation functions such as CPK, bad types of items, bad proportions, etc., which can provide a basis for improving the process in the production workshop;

6. Detection data output system: The screening machine has data communication functions, data output and storage functions, and the data exported by the software can be printed on paper through a local area network connected to a printer.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!