Product Description:

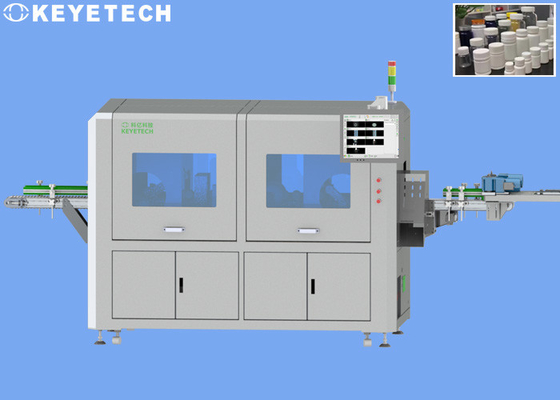

The Bottle Inspection System is an advanced, AI-driven bottle quality checker and verification system, offering superior bottle analysis capabilities. It is constructed with high-grade stainless steel for long-lasting durability, and its dimension is 3000x1200x1800mm. It is an ideal choice for businesses looking for a reliable bottle quality verification system. With its advanced AI algorithm, it can quickly and accurately detect any defects on bottles, ensuring that all the bottles produced are of superior quality. It offers a comprehensive HMI support, allowing users to conveniently manage and operate the system. The Bottle Inspection System is an outstanding choice for businesses looking for an efficient, reliable, and cost-effective bottle verification system.

Features:

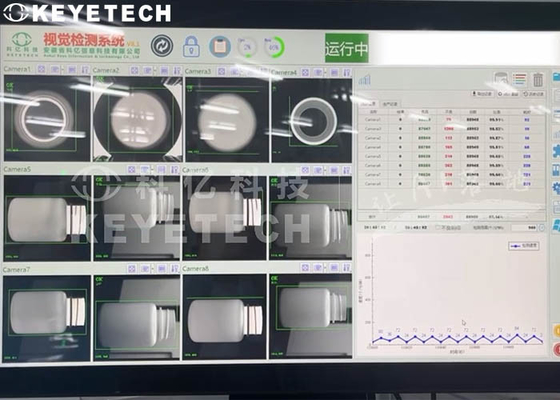

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 degree comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Applications:

KEYE's Bottle Inspection System (Model KVIS-B) is an advanced quality control solution designed to guarantee the quality of products during the manufacturing process. It is made in China and certified by CE/ISO/UL. With its high resolution 300 Megapixels camera (KEYE) and a main control board, it provides fast and accurate bottle quality analysis and evaluation with a rejection rate of ≤0.5%. The system is available in a dimension of 3000x1200x1800mm and comes with a minimum order quantity of 1 SET. Customers can choose from various payment terms such as TT, L/C, Paypal, or Credit Card, and delivery time is 6-8 weeks with the product being packaged in a plywood carton. KEYE's Bottle Inspection System is highly reliable with a supply ability of 30 sets per month.

KEYE's Bottle Inspection System is suitable for a wide range of applications such as bottle quality checker, bottle analysis system, and bottle evaluation system. It offers unparalleled accuracy for bottle inspection, ensuring manufacturers to have a quality-assured product. Its easy to use interface provides users with a hassle-free experience. With a competitive price, it is the ideal solution for any manufacturing process.

Customization:

KEYE KVIS-B Automatic Bottle Inspection System

- Brand Name: KEYE

- Model Number: KVIS-B

- Place of Origin: CN

- Certification: CE/ISO/UL

- Minimum Order Quantity: 1 SET

- Price: Negotiable

- Packaging Details: Plywood Carton

- Delivery Time: 6-8 weeks

- Payment Terms: TT, L/C, Paypal, Credit Card

- Supply Ability: 30 Sets Per Month

- Type: Automatic

- Camera: 300 Megapixels (KEYE)

- Control System: Main Control Board

- Rejection Rate: ≤0.5%

- Weight: 300-500Kg

KEYE KVIS-B Automatic Bottle Inspection System is a perfect solution for bottle measurement, bottle quality checking, and bottle analysis. It is designed to ensure the accuracy and reliability of the inspection process. With its advanced camera and control system, it provides a high rejection rate and excellent performance. This product is CE, ISO, and UL certified and has a minimum order quantity of 1 set. The delivery time is 6-8 weeks and the price is negotiable. It has a Plywood Carton packaging and the supply ability is 30 sets per month.

Support and Services:

Bottle Inspection System Technical Support and Service

We provide comprehensive technical support and service for our Bottle Inspection System. Our team of experienced engineers and technicians are available to provide support for the following areas:

- Hardware installation and maintenance

- Software installation and maintenance

- Troubleshooting and repair

- System training and support

- Product updates and upgrades

- Data analysis and reporting

We strive to provide the best customer service experience and are dedicated to helping our customers get the most out of our Bottle Inspection System. If you have any questions or need assistance, please contact us at any time.

Packing and Shipping:

Packaging and Shipping

Bottle Inspection System is packaged in a secure box and shipped with reliable carriers. Appropriate packing materials are used to ensure that the product and components arrive safely to the designated location.

FAQ:

- Q: What is the Brand Name of the Bottle Inspection System?

- A: The Brand Name of the Bottle Inspection System is KEYE.

- Q: What is the Model Number?

- A: The Model Number is KVIS-B.

- Q: Where is the Place of Origin?

- A: The Place of Origin is CN.

- Q: What are the Certifications?

- A: The Certifications are CE/ISO/UL.

- Q: What is the Minimum Order Quantity?

- A: The Minimum Order Quantity is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!