Machine Vision Inspection Is Widely Used In Intelligent Manufacturing

Company profile

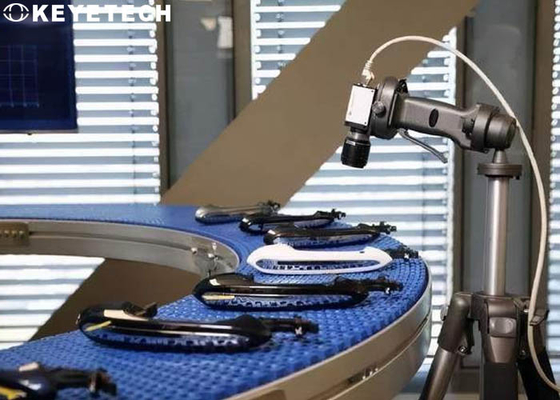

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Inspection principle

Intelligent manufacturing equipment is manufacturing equipment with the functions of perception, analysis, decision-making, and control. It is an important embodiment of the deep integration of informatization and industrialization, and it is also a key development direction of advanced equipment manufacturing. Intelligent manufacturing equipment mainly includes digital machine tools, 3D printing and so on.

There are many advantages of vigorously developing the intelligent manufacturing equipment industry, which can speed up the transformation of the manufacturing industry, improve production efficiency, reduce energy consumption, and realize intelligent manufacturing! As a new type of technology, machine vision inspection has the characteristics of high intelligence and strong environmental adaptability, and has been widely used in various intelligent manufacturing equipment.

Significance of machine vision

Machine vision detection technology is an intelligent measurement and control technology that uses machine vision to replace human eyes and hands for detection, measurement, analysis, judgment and decision-making control. Compared with other detection technologies, its advantages mainly include: high degree of intelligence, comprehensive information collection , High detection rate, high precision and so on.

At present, the intelligent manufacturing equipment industry is developing rapidly. In the process of independent innovation, there is a huge and urgent demand for intelligent technologies such as machine vision detection and control. In the process of manufacturing products, the generation of surface defects is often unavoidable. Surface defects not only affect the beauty and comfort of products, but also generally have adverse effects on their performance. Therefore, manufacturers attach great importance to the detection of surface defects in order to find them in time and effectively control product quality.

Manual inspection is a traditional detection method of industrial vision for product surface defects. This method has low sampling rate, low accuracy, poor real-time performance, low efficiency, high labor intensity, and is greatly affected by manual experience and subjective factors. Machine vision-based Industrial visual inspection methods can largely overcome the above drawbacks.

Applications

- Component surface defect feature detection, character printing defect detection, component damage detection, chip pin package integrity detection, terminal PCB (component surface defect feature detection, character printing defect detection), IC chip (gold-plated surface defect), etc.;

- In terms of new energy, it can be used for surface defect detection of synchronous motor hairpin coils, etc.;

- In terms of mechanical manufacturing, it can detect engine gaskets and car appearance defects, etc.

- Defect detection of automobile instrument panel, defect detection of automobile and motorcycle parts, defect detection of plastic parts of automobile and motorcycle lamps, etc.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!