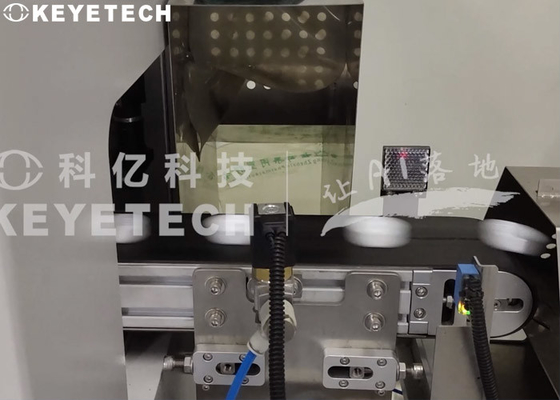

Automatic Online Machine Vision System for Cap Inspection & Sorting

Inspection standard

| Item |

Bottle caps inspection machine |

Main Material |

Stainless steel |

| Weight |

500kg |

Size |

4250*1650*1860mm |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Current |

4kw |

Air Pressure |

0.5-0.8Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

Depending on the specific situation

|

Inspection principle

Bottle caps are an important part of food and beverage packaging, and they are also the first place where consumers come into contact with products. The bottle cap has the function of keeping the content product airtight, and also has the functions of anti-theft opening and safety, so it is widely used in bottled products, so the bottle cap is the upstream industry of food, beverage, wine, chemical industry and pharmaceutical industry. It is a key product of bottle container packaging.

Since bottle caps are an important part of the printing and packaging industry, strong changes in downstream consumer market demand will directly affect the market demand for bottle caps, and the vigorous development of the beverage industry has higher and higher requirements for product packaging. The quality of the cover is very necessary.

Vision solutions

The machine vision defect detection system converts the bottle cap into an image signal through an industrial camera, transmits it to the image software processing system, and converts it into a digital signal according to information such as pixel distribution and brightness. The image software processing system performs operations on these signals to extract the original bottle cap image features for judgment and comparison, and provides the bottle cap detection results in real time, correspondingly outputs ok and ng signals, automatically saves the detection data, and realizes intelligent detection.

The main items of inspection include: bottle cap damage detection, bottle cap height detection, bottle mouth defect visual detection, liquid level detection, bottle body labeling detection. Compared with traditional manual naked eye inspection, machine vision inspection has high precision, high efficiency, good continuity and can generate reports.

Importance of machine vision

In order to ensure the quality of bottle caps in production, it is necessary to do a defect detection. However, due to the limitations of manual detection, the detection results are inconsistent and the detection efficiency is difficult to improve. At this time, we need machine vision to detect, and the accuracy rate far exceeds human eye detection. At the same time, the subjective factors of the inspectors can be excluded, and the reliability is higher. Therefore, the replacement of human eye detection by machine vision detection will be an inevitable trend in future development.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.

During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!