Black Spot Detection Equipment On The Film Production Process

Technical parameters

|

1. Measurement accuracy: spots, stains, holes and other defects above 0.1mm

|

| 2. Applicable width: customized according to requirements |

| 3. Number of CCDs: determined by the width of the measured object and detection accuracy |

| 4. Detect common defects, process defect information, and provide real-time defect location, size, and records for user reference and verification |

| 5. The system can set the parameters of the defect alarm, and the user can set the alarm line according to the production requirements, realize the sound and light alarm and mark the unqualified position online. |

Inspection background

The surface flaws of industrial products seriously affect the quality of the product itself. How to avoid surface flaws and carry out quality control has always been the biggest problem facing manufacturers. The traditional manual inspection is not only expensive, the inspectors are prone to fatigue, and defects are easily missed. However, it has been difficult to adapt to the high-speed production system. It is necessary to know that the application of intelligent visual inspection in industry provides a new solution for surface defect detection.

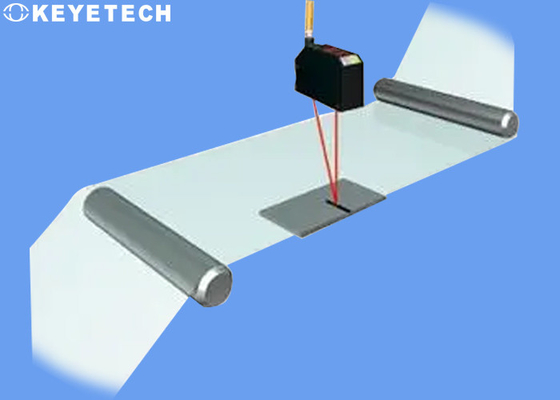

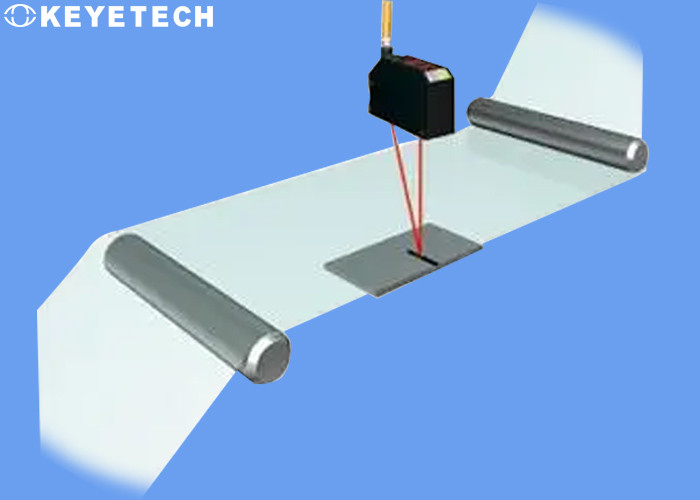

Inspection principle

The film surface inspection system is mainly used to detect black spots, crystal points, scratches, holes, lines, wrinkles, mosquitoes and other defects on the surface of the film during the production process.

With the aid of an imaging system for film surface defect detection consisting of an industrial CCD camera and a high-brightness LED linear concentrating light source, it can timely and accurately reflect specific information such as the picture, shape, size and position of the defect, and provide quality control and product rating. While providing accurate data, it effectively saves production costs and improves product quality.

Inspection details

For thin film materials with high light transmittance, the system adopts the transmission lighting detection method for detection, that is, the light source is below the film, and the camera is above the film for image shooting (for opaque materials, the reflective lighting method is used, that is, the light source on the same side of the surface to be inspected as the camera).

When the production line is running, the system collects the real-time running status information of the production line through the encoder and starts to detect. The system uses the image collected by the camera to process the defect through the precision measurement and control image analysis software. Because the defect and the image of the normal product are on the gray scale There are obvious differences, so that the system can find the flaws, and determine the size, location, type and other information of the flaws through further calculation and analysis.

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!