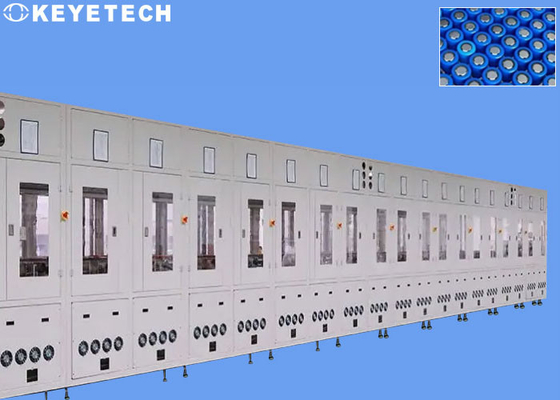

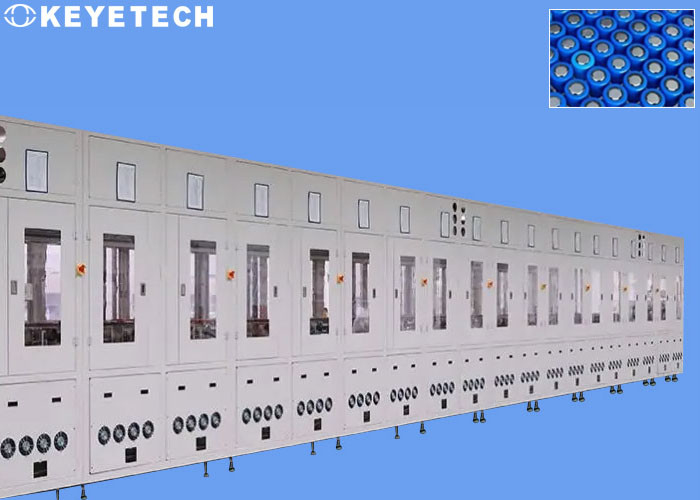

Online Surface Visual Inspection System Of Lithium Ion / Battery Films

Equipment features:

| 1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

| 7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Inspection principle

The method of detecting some process defects of lithium batteries is still manual measurement and judgment. During the detection process, it will be affected by human factors such as the subjective will, emotion, and visual fatigue of the inspectors, resulting in large errors and slow detection results. The machine vision inspection system can replace manual inspection, avoid inspection shortcomings, make inspection results standardized and quantifiable, further improve the automation of the entire production system, save labor costs, and realize cost reduction and efficiency increase for enterprises.

How to highlight the detection information such as size and defects is the difficulty of machine vision processing. This article will share the application case of Jingzhi Vision 3D measuring instrument in the appearance and defect detection of lithium batteries, and further analyze how to detect poor quality in the production process of lithium batteries.

Functions of system

The KEYE TECH system can accurately locate the defect position through the height information of the three-dimensional image, and the detection accuracy can reach 0.1mm. Through the self-developed 3D point cloud processing algorithm, it can efficiently complete the detection of the quality of the front and rear shells of the lithium battery, reducing customer Reduce production costs and simplify production management processes.

Lithium battery appearance defect detection system is a customizable product for the lithium battery production industry. It is equipped with high-precision 3D measurement equipment independently developed by Jingjing Vision, as well as high-performance point cloud and image processing algorithms, realizing fully automatic loading. , detection, blanking function. The system is composed of two parts: automatic control system and visual inspection system. It supports multi-device connection, account authority login, algorithm strategy custom combination, online display of results, image storage, data statistics, PLC communication and other functions.

equipment provides an effective solution for enterprises to ensure product quality.

Inspection result

The system adopts high-precision linear track slide table, high-precision rotary platform, high-precision fixture platform, high-reliability motor and control system to realize the automatic process of battery loading, testing and unloading.

It is mainly used to detect defects such as pits, bulges, and scratches on the appearance of lithium batteries. According to the system algorithm and user-defined industrial parameters, the detection results are output in real time, and the lithium batteries are automatically sorted into qualified and unqualified products through the automatic mechanism. Moreover, the system is compatible with the MES industrial system, which is convenient for real-time synchronous detection of statistical data.

Our advantages

KEYE TECH implements a customized detection system according to each production link of lithium batteries to help the intelligent upgrading of lithium battery production. At present, Jingyou Vision has cooperated with many lithium battery equipment manufacturers and successfully applied it in lithium battery production lines. In the future, Jingquality Vision will also cooperate closely with midstream equipment manufacturers, based on downstream product iterations and process innovations, including coating, rolling, slitting, laser die-cutting/hardware die-cutting, winding, lamination and other processes. , and provide customized visual inspection application solutions for different enterprises.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!