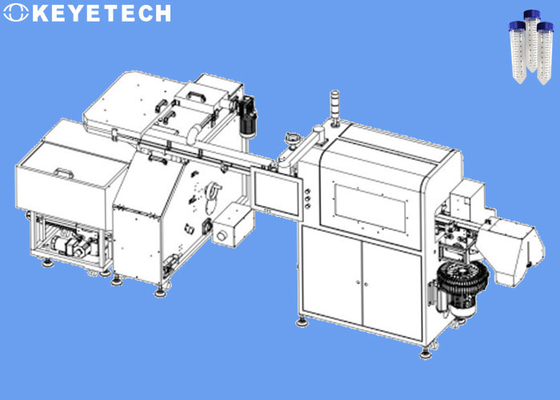

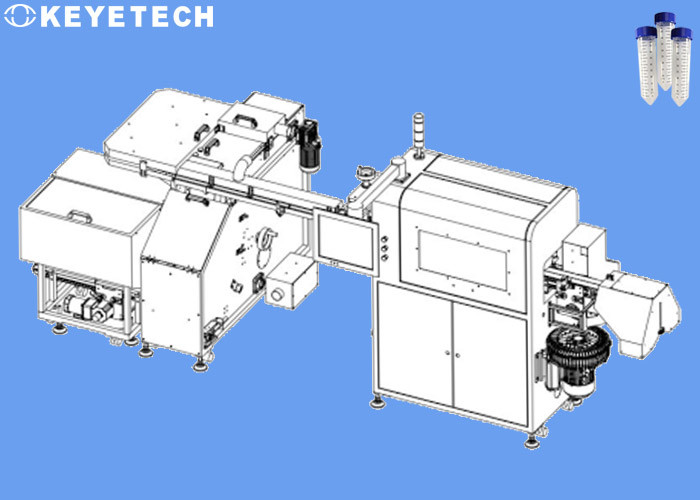

Lab Containers Visual Inspection Systems For 50ml Centrifuge Tube

Equipment features:

| 1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

| 7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Product background

As an indispensable step in the manufacturing process, surface defect detection is widely used in various industrial fields, including 3C, semiconductor and electronics, automotive, chemical, pharmaceutical, light industry, military and other industries, giving birth to many upstream and downstream enterprises. Since the 20th century, surface defect detection has roughly gone through three stages, namely manual visual inspection, single electromechanical or optical technology inspection, and machine vision inspection.

Machine vision is the eye of the 5G industry and the key to realizing industrial intelligence and data. It has strong machine characteristics, such as extremely high speed, accuracy, repeatability, etc., far beyond human eye recognition; at the same time, industrial machine vision has the ability to collect a large amount of field data, and is the most important data entry for future industrial production. . As one of the frontier branches of artificial intelligence, the development of artificial intelligence and the penetration of intelligent manufacturing equipment will double accelerate the progress of machine vision.

Inspection principle

The centrifuge tube cover appearance detection equipment through the docking front automation mechanism (can directly contact the conveyor line, the waterfall cover machine, the centrifugal turntable and multiple typing mechanisms, specifically based on the production site to determine),the pharmaceutical packaging bottle cap are stably transmitted to a specific detection station.Then transmitted the shooting high-pixel sample image to image processing software by industrial camera, detecting and determining a good product and defective product via AI manually intelligent algorithm, and controlling the corresponding pneumatic components to remove the defective product, and finally get the qualified product. The detecting machine rear end conveying platform can interface the automated packaging mechanism.

There are plastic and glass centrifuge tubes commonly used in laboratories. Generally, plastic centrifuge tubes are used more, because glass centrifuge tubes cannot be used in high-speed articles from: genintech.com or ultracentrifuges. Plastic centrifuge tubes are also made of PP (polypropylene), PC (polycarbonate), PE (polyethylene) and other materials. The performance of PP pipes is relatively good. The plastic centrifuge tube is transparent or translucent, which can visually see the centrifugation of the sample, but it is relatively easy to deform, and has poor corrosion resistance to organic solvents, so the service life is short. Therefore, laboratories generally buy centrifuge tubes frequently.

Features of system

- AI algorithm: high stability, can adapt to the disturbance of the environment and background; after training, it can automatically identify different defect samples.

- Dataization: independent database, save a variety of samples, analyze defective products, and keep historical records.

- Multi-directional: 360° omnidirectional inspection without dead angle on the outside of the centrifuge tube cover.

- Visualization: real-time display of sample images, running status, real-time statistical inspection results and defective product defect classification information.

- High precision: The detection accuracy rate can reach 99.5%.

- Modular, can flexibly increase or decrease the detection function according to the actual needs of customers.

- Easy to operate: The equipment is easy to operate and easy to maintain.

- Safety: Made of medical-grade materials, it fully conforms to the production environment of medical supplies.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!