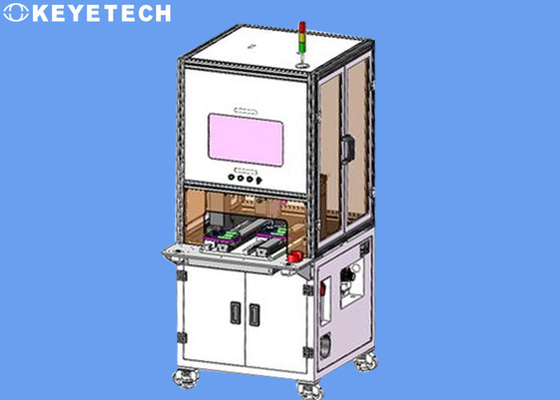

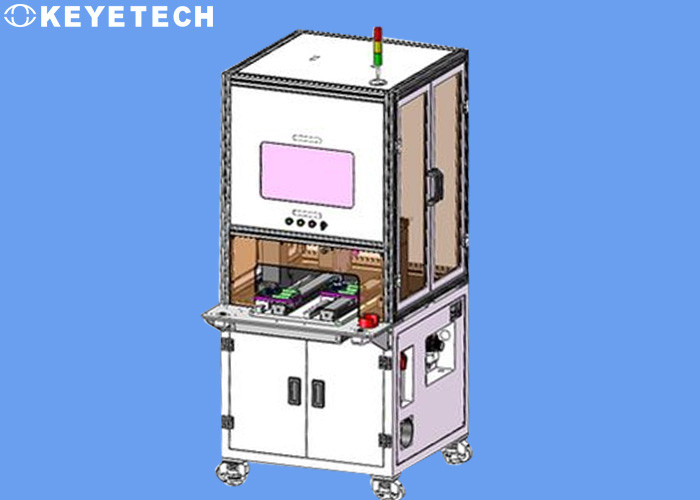

30 CC-100 CC Tablet Bottles Visual Inspection System With Deep Learning Algorithm

Testing standards

| Model |

Camera |

Scope Of Test |

Test Content |

Precision |

Accuracy |

Speed |

|

Kvis-Sc10

|

1set |

Bottle Mouth Area |

Black Spots, Stains,

Impurities

|

≥0.2mm |

99% |

200-500pcs/min |

| Flash, Lack Of Material |

≥1.0mm |

99% |

| 4 Sets |

The Upper Area Of The Bottle Body |

Black Spots, Stains,

Impurities

|

≥0.2mm |

99% |

| Bubble |

≥1.0mm |

99% |

| 4 Sets |

Lower Area Of Bottle |

Black Spots, Stains,

Impurities

|

≥0.2mm |

99% |

| Bubble |

≥1.0mm |

99% |

| 1 Set |

Outer Bottom Of Bottle |

Black Spots, Stains, |

≥0.2mm |

99% |

| Impurities |

≥1.5mm |

99% |

|

Hole

|

≥1.0mm |

99% |

Detection Principle

Due to differences in raw materials, unstable mechanical equipment and insufficient manual operation, plastic products are prone to product quality defects during the injection molding process. Common injection molding defects include insufficient filling, air bubbles, cracks, warpage, and dimensional changes.

The traditional artificial visual defect detection method is time-consuming and labor-intensive, and it will provide the possibility for efficient detection. As one of the most classic and most widely used structures in deep learning, deep convolutional neural network has been successfully applied to image detection in the past. and classification fields. It also provides a feasible method for industrial defect detection.

Image processing

A 3-megapixel industrial camera was used to collect and extract image samples of special plastic bottles, and preprocessed them. Because plastic bottles usually have color-like characteristics, the HSV color space conversion is used to extract color features on the sample image, and the Otsu threshold is used to segment the feature part, which is beneficial to neural network training, reducing the difficulty of network training and improving the speed.

Label the samples. Manually mark the bottles for defects. Considering the high time cost and labor cost of manual labeling, it is recommended to use the intelligent labeling system for industrial quality inspection provided by the wizard labeling assistant. You only need to focus on labeling about 30% of the key pictures of the data set, and you can label the remaining pictures with one click. Easily obtain high-quality object detection models. The system can be used on different operating systems with cross-platform, multi-language and compatibility.

Algorithm Accuracy and Computation Rate

The detection of plastic medicine bottle defects mainly uses "convolutional neural network". One of the representative algorithms of deep learning). The schematic diagram of the convolutional neural network structure is as follows:

For neural networks, as the network becomes larger and channels increase, the accuracy will increase, but it will saturate after reaching a certain level; when the accuracy decreases, it will suddenly fall into a situation where it cannot learn. For the requirements of higher accuracy and high speed of the model, while thinking about large neural networks, there are often many channels. Existing neural networks, such as GoogleNet, even have many networks with side branches; after ResNet, the number of network layers is also deepened; based on depth The convolutional neural network realizes the automatic detection of plastic drug surface defects, avoids the time-consuming and laborious manual visual inspection, reduces the labor cost, and greatly improves the inspection quality, improves the production efficiency, and reduces the false detection rate.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!