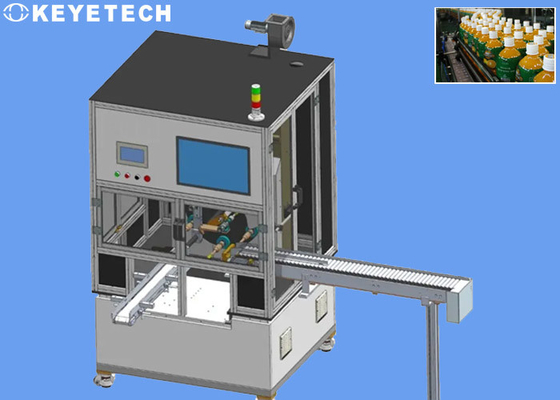

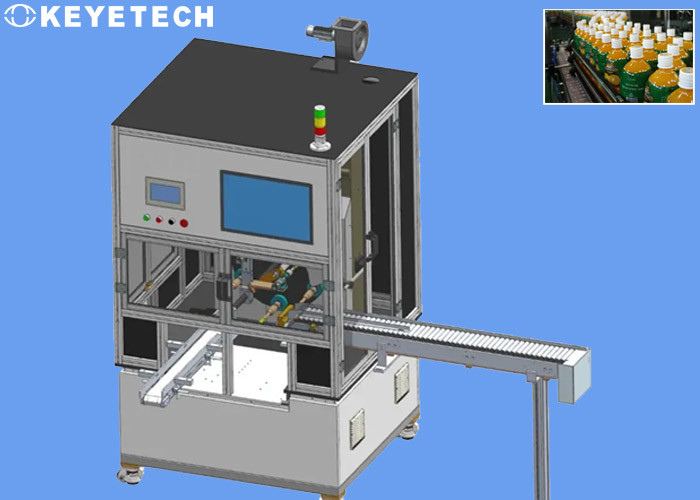

HD Industry Camera Visual Inspection System For Food And Beverage Production

System description

The system adopts imported high-resolution industrial cameras, which can quickly acquire images. Through image recognition, analysis and calculation, it can detect whether there are defective products in button production in real time, and output corresponding detection signal prompts to facilitate the processing of defective products.

| Model |

Number Of Camera |

Inspection Scope |

Inspection Content |

Detection Precision |

Accuracy |

Capacity |

| Kvis-Cc06 |

4 set |

Outside Surface |

Black Spot≥0.2mm |

99.8% |

99% |

500pcs/min |

| 0.5mm<Flash, Injection Incomplete≤1mm |

99% |

| 1set |

Concave Surface |

0.5m<Injection Incomplete≤1mm |

99.8% |

| Black Spot≥0.2mm |

99.8% |

| 2mm<Transformation |

99% |

| 1set |

Trademark Surface |

Black Spot≥0.2mm |

99.8% |

| Note: The System Equipped With 2 Million Pixel-Level Industrial Cameras. |

Inspection details

1. Packaging appearance quality inspection

Extract the cigarette pack image and convert it into digital image information, send it to a dedicated image processing system, perform various operations on these signals according to pixel distribution, brightness, color and other information to extract the characteristics of the target, and then control the culling action according to the results. . Realize comprehensive quality monitoring of cigarette packs on high-speed running machines, effectively avoid mislabeling, warped edges, whitening, bottom edge opening, reverse packs, damage, deformation, etc.

2. Inspection of the appearance of cigarettes

The high-speed cigarette machine has a very fast production speed, and the cigarette detection system is an indispensable packaging quality control component in the cigarette packaging machine.

3. Identification of anti-counterfeiting code

Coding technology refers to the printing of serial numbers, expiration dates, batch numbers, logos, brand names and other information on various packages of smoking products, and is widely used in the manufacture of smoking products. The detection of the anti-counterfeiting code mainly focuses on the detection of the anti-counterfeiting code of the transparent outer wrapping paper of the small package.

4. Sealing misplacement and deletion detection

The top seal of soft-pack cigarettes is used as a sign of the relevant information of cigarettes. In the process of cigarette packaging, it should be ensured that the position of the seal is correct and cannot be missing. A detection device is needed to monitor in real time to ensure that each box is The quality of the cigarette's seal. The machine vision technology has the advantages of simple setting, powerful image grayscale analysis function, and large grayscale recognition range, which can realize the identification of the seals of cigarettes from different manufacturers, and improve the stability of the packaging machine.

Function of Vision Machine

The machine vision system uses machines to replace the human eye to make various measurements and judgments. It is an important branch of computer science. It integrates technologies such as optics, machinery, electronics, computer software and hardware, and involves many fields such as computer, image processing, pattern recognition, artificial intelligence, signal processing, and opto-mechanical integration. . The rapid development of technologies such as image processing and pattern recognition has also greatly promoted the development of machine vision. It is invaluable in its ability to detect defects and prevent defective products from being shipped to consumers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!