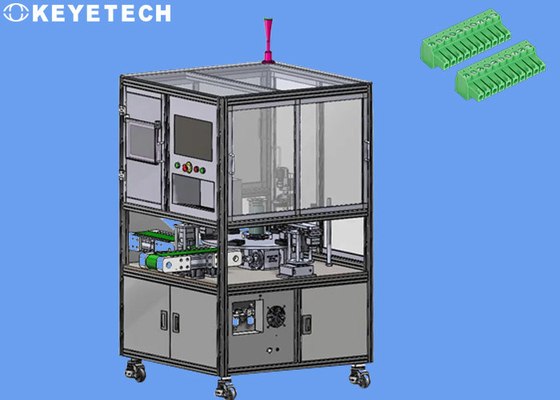

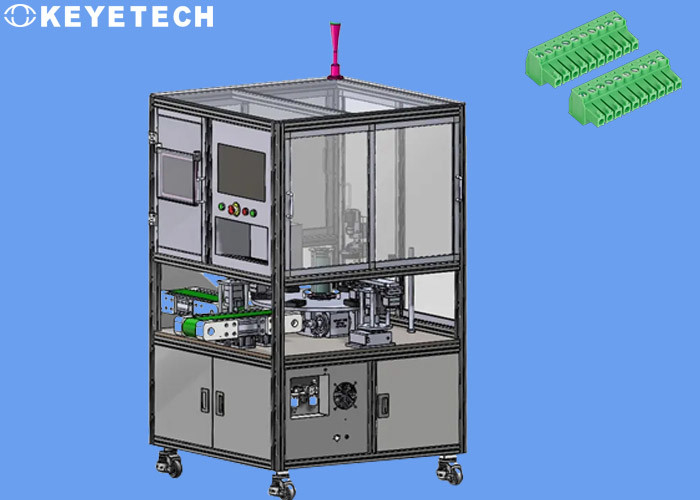

Visual Inspection Machine Check Quality Control System For Pin Connector

System Operating Parameters:

| System operating parameters |

| System size |

See design drawings for details |

Voltage and current |

220V 20A 50HZ |

| Equipment Power |

5.0-6.0kw |

Compressed Air |

0.5~0.8Mpaclean And Oil-Free |

| Ambient Temperature |

-20℃ ~ 60℃ |

Environment Humidity |

Below 50% Relative Humidity |

Inspection principle

As a device that transmits current or signals to connect two active devices, connectors are widely used in various industries, from mobile phones, tablets, computers, to refrigerators, air conditioners, washing machines, to automobiles, national defense, and aviation. It is everywhere. . Every electronic product will not be able to operate without connectors. Therefore, there are strict requirements on the quality of its size and appearance, and the inspection work must not be missed.

As the function of the connector continues to increase, its structure becomes more and more complex, and the volume becomes more and more miniaturized, and the difficulty of connector size measurement and appearance defect detection is also increasing. Traditional manual inspection methods are increasingly unable to meet the quality inspection requirements of connector products. Machine vision automatic inspection equipment must be used to ensure the accuracy, efficiency and accuracy of inspection.

Inspection details

Machine vision inspection equipment measures and inspects products by replacing human eyes with machines. The captured target is converted into an image signal by a machine vision product (ie, an image capture device), which is sent to a dedicated image processing system, and converted into a digital signal according to pixel distribution, brightness, color and other information; the image system performs various The operation extracts the characteristics of the target, and then controls the operation of the equipment in the field according to the result of the judgment.

KEYE TECH visual inspection equipment can realize the automatic process of connector size measurement and appearance defect detection, automatic feeding, automatic detection, automatic sorting, automatic unloading, and automatic rejection of defective products.

Advantages of system

The equipment can quickly and accurately detect various defects such as burrs, deformation, scratches, crushing, material shortage, chromatic aberration, blind holes, etc. of connectors. It can also measure the outline dimensions of connectors and other data to efficiently and quickly judge whether the product is qualified or not. Using machine vision inspection equipment to replace manual inspection can avoid these problems, better meet the requirements of modern manufacturing, improve production efficiency, and ensure the quality of product shipments.

The traditional connector appearance inspection method mainly relies on manual operation by inspectors. The specific method is to perform visual inspection or semi-automatic measurement with inspection tools such as micrometers, magnifying glasses, and three-coordinate measuring instruments. The traditional detection method is very slow, low in accuracy, and low in detection efficiency. Moreover, due to the differences in the standards of the inspectors, people are also easily fatigued, which can easily lead to misjudgment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!