Inspection background

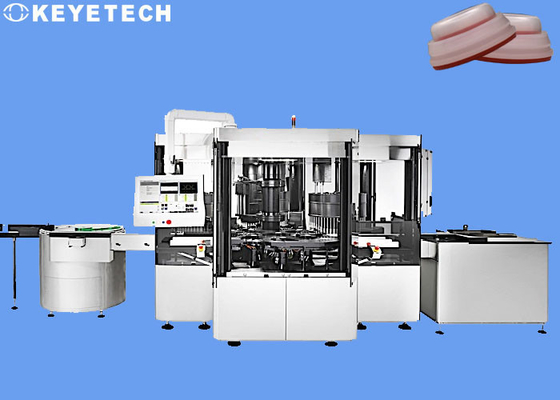

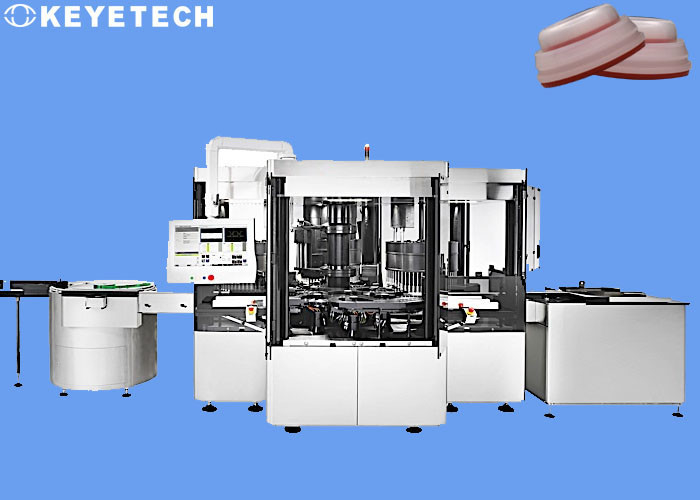

The bottle cap inspection machine system is based on machine vision technology. It is an application of non-contact and non-destructive automatic inspection technology in the detection of bottle cap defects. It is an effective means to realize automation, intelligence and precision control. Accuracy, simple and convenient operation, and long-term work in harsh environments are outstanding advantages.

The detection system obtains the surface image of the product through the appropriate light source and image sensor, uses the corresponding image processing algorithm to extract the feature information of the image, and then performs the positioning, identification, grading and other operations of surface defects according to the feature information, statistics, analysis and other operations. In order to achieve the purpose of eliminating defective products, retaining good products and improving the quality of bottle caps.

Inspection details:

Our design scheme uses 7 high-pixel industrial cameras and high-performance stroboscopic light sources to perform all-round visual inspection of bottle appearance defects and bottle bottom defects. The detection speed is about 120 pcs per minute, the equipment can run 7*24 hours all-weather detection, and unqualified products can be automatically eliminated online.

The complete set of inspection equipment includes mechanical parts, visual electronic hardware and inspection system software. The entrance and exit of the testing machine can be connected with the on-site transmission line, and the upstream and downstream production equipment can be connected on site according to the specific production requirements of customers.

The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

Features of system

1. The bottle cap inspection machine is equipped with a waterfall cap arranging machine, and can also be interconnected with a leak tester and a baler to realize the automation of the entire process from cap arranging to detection, counting and packaging;

2. 360° no dead angle, all-round detection and elimination of defects such as flash shortage, black spot contamination, deformation, gasket and other defects of bottle caps;

4. Under special conditions, the unique special prism can be used to realize multi-angle detection;

5. It can be equipped with 2-8 cameras according to the category requirements of actual detection of defects, with an accuracy of 0.1mm-0.3mm;

6. Applicable to all kinds of bottle caps: anti-theft caps, combined caps, butterfly caps, Epoxy caps, aluminum-plastic caps, etc.;

7. Small footprint, simple operation, and manual and automatic switching options are available;

8. Ai deep learning is good at handling all kinds of complex inspection projects, recording, analyzing and statistics of production data, and realizing the automation and intelligence of quality inspection.

System Operating Parameters

In actual testing, due to the critical fluctuation state of some testing item data, it can be adjusted through the parameter setting of the system software to achieve the actual effect.

| Size |

As drawing pic |

Voltage |

220V 20A 50HZ |

| Power |

5-6Kw |

Air compressed |

0.5~0.8MPa |

| Environment temperature |

-20℃ ~ 60℃ |

Environment humidity |

Below 50% relative humidity |

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.

During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!