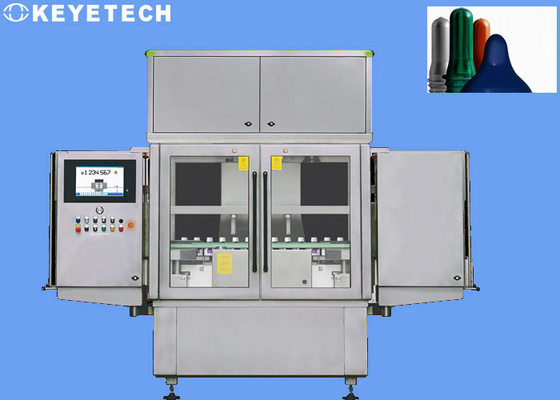

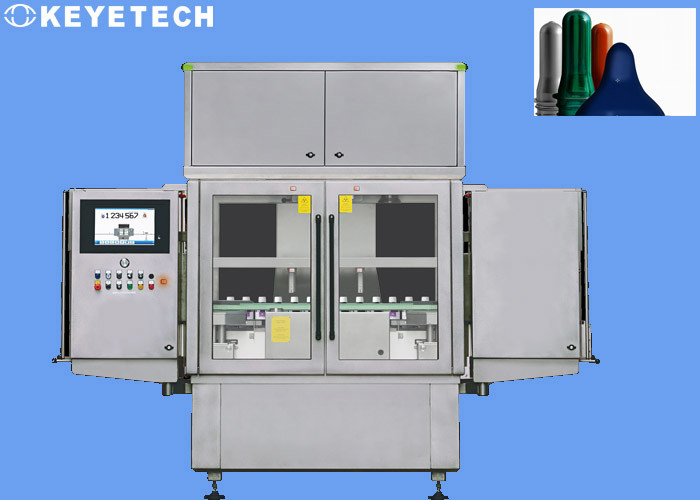

Mechanical Mechanism Visual Inspection System For PET Preforms

Inspection details

| Model |

Cameras |

Detection range |

Detection content |

Detection accuracy |

Accuracy rate |

False detection rate |

Detection speed |

| KVIS-SC10 |

4set |

Around the bottle preform |

Black spots, bubbles, impurities (different colors) |

≥0.3mm |

99% |

≤0.2% |

70pcs/min

|

| 1set |

Preform base |

Black spot, hole |

≥1.5mm |

99% |

≤0.2% |

| 4set |

Opening of the preform |

Black spots, stains, impurities (different colors) |

≥0.2mm |

99% |

≤0.2% |

| Overlap, lack of material |

≥1mm |

99% |

≤0.2% |

| 1set |

Support ring |

Lack of material |

≥1mm |

99% |

≤0.2% |

Market background

Preforms are semi-finished products of plastic-packed bottles, and appearance defects are unavoidable. The emergence of machine learning-based preform appearance inspection machines has provided a scientific and efficient solution for many industries to remove the poor appearance of preforms and improve the yield rate.

The appearance of the preform is not good, mainly manifested in flash, dirt, lack of glue, air bubbles, broken bottle mouth, etc., which not only cause a lot of waste of raw materials, but also cause the loss of important customers, causing huge economic and image losses to the enterprise.

Features of system

In response to customer pain points and market demands, the "preform machine inspection machine" online inspection system for appearance defects adopts machine vision technology and replaces human eyes with machines, which can quickly and efficiently complete the automatic detection of each preform under non-contact conditions. Screening and rejecting can increase the yield to above 99.9.

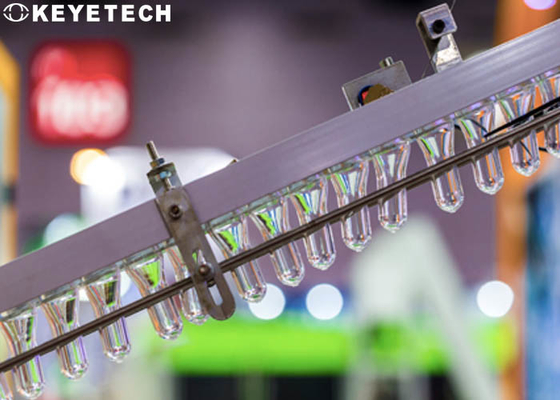

The multiple industrial cameras of the preform vision inspection system work at the same time, which can realize 360° all-round inspection of preforms without dead ends. The relevant production data and pictures can be statistically fed back to the smart factory or intelligent manufacturing system to realize the quality inspection of plastic package products. intelligent management.

In addition to providing preform appearance inspection, it can also be equipped with a variety of auxiliary machines such as preform sorting machines, so as to realize the integrated operation process of preform inspection, material sorting, and packaging, helping enterprises to improve the level of automation, realize unmanned operation, and reduce the cost of enterprises. labor costs.

Our service

In addition to providing preform appearance inspection, it can also be equipped with a variety of auxiliary machines such as preform sorting machines, so as to realize the integrated operation process of preform inspection, material sorting, and packaging, helping enterprises to improve the level of automation, realize unmanned operation, and reduce the cost of enterprises. labor costs.

Our company have served many well-known enterprises such as Coca-Cola, P&G,Unilever,ALPLA,C'estbon, Nongfu Spring, etc., and has won praise from many users.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!