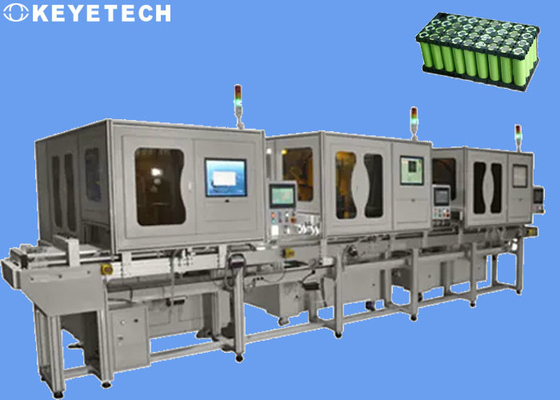

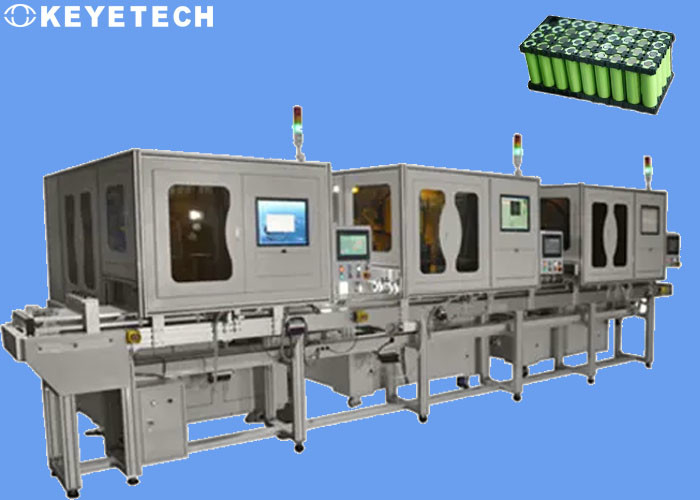

Full Automated Visual Inspection Machine For Lithum Battery Surface Checking

Features of system

|

1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

|

| 2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

| 7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Product background

As the global energy crisis and environmental pollution problems become increasingly prominent, the development of related industries such as energy conservation and environmental protection is highly valued, and the development of new energy vehicles is also a national strategy for energy conservation and emission reduction, not only for passenger cars, but also various types of vehicles. Engineering vehicles have a trend of electrification, so major car companies have launched new energy vehicles, and power batteries are an indispensable part of new energy vehicles.

Machine vision inspection technology plays a vital role in industrial automation, and it has become the driving force for factories and enterprises to improve production efficiency and product quality. Machine vision detection has been widely used in various industries, and plays a particularly important role in the detection of new energy batteries.

Application site

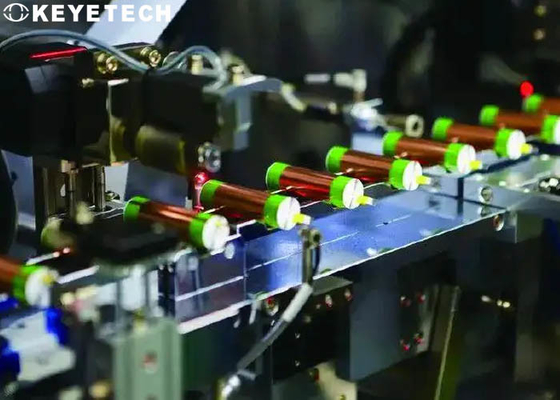

1.Battery pole piece alignment detection, such as: blank size, coating width size, whether the upper and lower coatings are aligned, etc.; battery pole piece burr detection, automatically determine the burr shape and size;

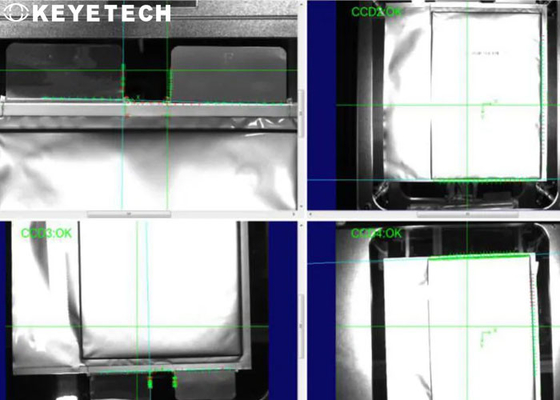

2. Appearance defect detection of battery laminations, such as: diaphragm wrinkling, long glue wrinkling, long glue skew, uneven lamination, uneven diaphragm, inner folding of the diaphragm, etc.; battery packaging appearance defect detection, such as: packaging wrinkle, Defective electrode pressure ear, bad electrode ear glue, pressure injury, pinched injury, corner pit, etc.;

3. Cell thickness measurement and appearance defect detection, such as: breakage/liquid leakage, pole piece folded, foreign objects in edge sealing, bumps, depressions, scratches/indentations, dirt, surface wrinkles, etc.; battery code reading and Side glue detection. Such as: poor glue, poor code scanning, poor external dimensions.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!