High Precision Plastic Cap Closures Automatic Vision Inspection System

Company Profile

Keye Technology relies on the Keye Laboratory of Pattern Recognition of the University of Science and Technology of China, and has a high-level doctoral R&D team covering the entire technology chain of optics, mechanics, electricity, computing and software.

Through the project practice in the fields of packaging containers, 3C, medicine, textile, food, etc., the KVS-AI software and hardware platform has been created, so that AI technology can be transformed into real productivity. We provide visual imaging, algorithm computing power and automatic control AI system solutions for various sub-industries.

Features of AI Algorithm

- Accuracy of results: Compared with traditional vision algorithms, the stability of deep learning algorithms is greatly improved, and it can adapt to general disturbances in the environment and background. At the same time, the accuracy of the algorithm is also higher than that of traditional vision algorithms;

- Algorithm versatility: For different defects, only a small number of defect samples need to be collected. After sufficient training, different defect samples can be automatically identified. The algorithm adopted is a unified algorithm framework;

- Development timeliness: Since there is no need to develop algorithms for different defects, the entire development cycle is greatly shortened, and general visual defect projects only need 2-3 hours to go online for testing;

- Environmental reliability: Due to the guarantee of GPU computing power, the entire system can work in a high-temperature environment for a long time with sufficient computing power margin.

Inspection Principle

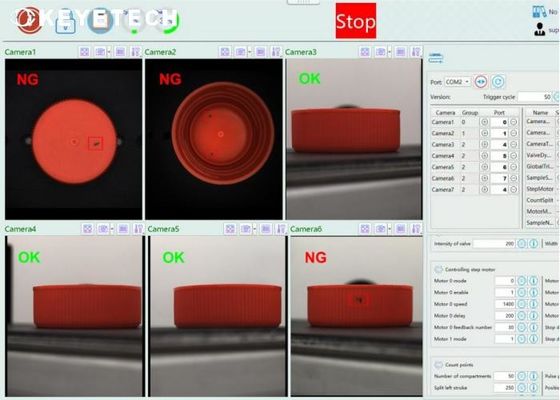

KEYE Camera inspection system consists of material handling system, vision system, software system, central control system and execution system. The detected objects are sorted through the material sorting system to ensure that the detected objects are oriented in the same direction and evenly distributed.

Then enter the vision system to take 360° images of the detected objects, and transmit the image data to the software system to identify the detected objects. Sorting, issuing rejection and sorting instructions to the execution system.

Software Function

- Enabling and disabling the system detection function

- Detection index parameters and accuracy adjustment

- Template sampling and saving, storage and retrieval of sample information

- Camera screen calibration function

- Real time production information display of the system (qualification rate, total output, speed, etc.), browsing of historical production information, export and storage functions

- Manage permissions based on login account

- (example, disabling parameter adjustment for general operation users)

- Operation and adjustment of the mechanical part of the system (If the transmission device is turned on, adjust the alarm signal)

After-sale Service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!