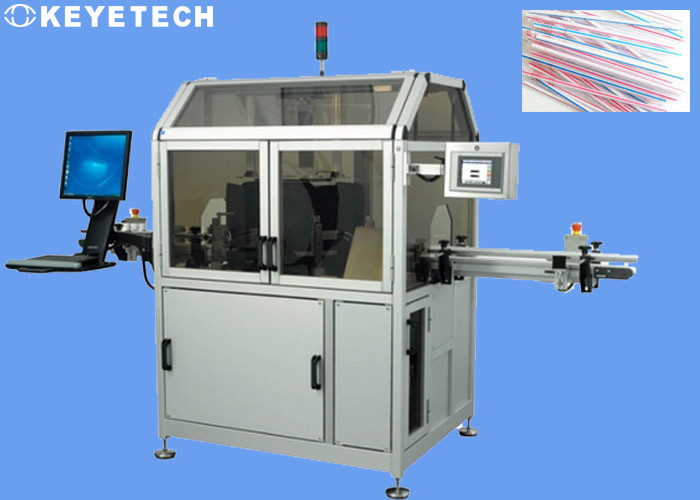

Full Automated Vision Inspection Systems For Disposabel Drinking Straw

Inspection details

| Application |

Drkinking straws |

| Sample |

U-tube, telescopic tube, pointed tube,etc. |

| Inspect |

Size, dents, black spots, color difference, wrinkles, damage,eitc. |

| Precision |

0.05mm |

| Speed |

80,000pcs/h |

Product background

In the production process of straws, it is inevitable that there will be appearance defects, such as body length, body short, oil stains, black spots, etc., which will have a great impact on the quality of straws. Relying on machine vision technology, our company has developed an intelligent straw quality inspection system using industrial cameras and image processing technology, which has reached the level of industrial applications in terms of speed and accuracy. The system is used for external defect detection, internal defect detection and color sorting of various types of straws (white, striped, etc.) for straw manufacturers and dairy manufacturers.

During the packaging process of beverage straws, there will be quality problems of overlapping dislocation and missing. Traditional manual screening is not only inefficient, but also prone to missed inspections and other phenomena. Through visual inspection, it is not only efficient, but also there is no missed inspection, ensuring that no defective products will flow out, and improving the pass rate of products.

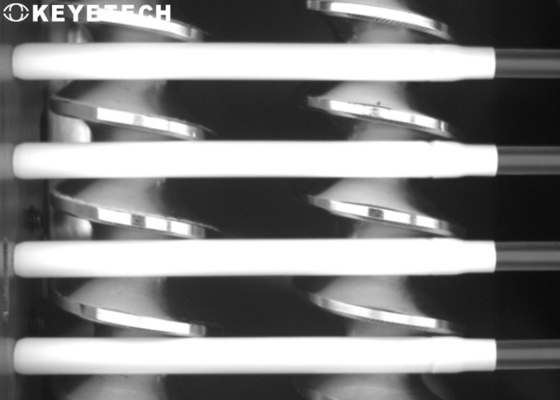

Inspection principle

In view of the problems existing in the prior art, the purpose of the present invention is to provide a visual detection device for drinking straws, wherein the visual detection device for drinking straws is provided with an upper detection light source, an upper camera, a lower detection light source and a lower camera with The function of adjusting the distance between the tube and the material, and the upper and lower cameras also have the function of adjusting the inclination angle, so as to reduce the misjudgment rate of the visual inspection device, improve the detection accuracy and detection efficiency of the visual inspection device, and set the The upper cover and the lower cover are convenient to switch, which brings great convenience to the adjustment of the upper detection light source, upper camera, lower detection light source and lower camera.

Features of system

- AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history

- Multi-orientation: 360 ° comprehensive inside and outside the samples

- High precision: detection accuracy can be high

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs

- Easy to operate: It is easy to operate and easy to maintain

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!