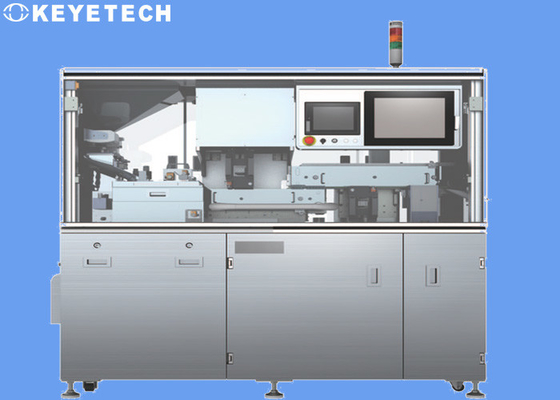

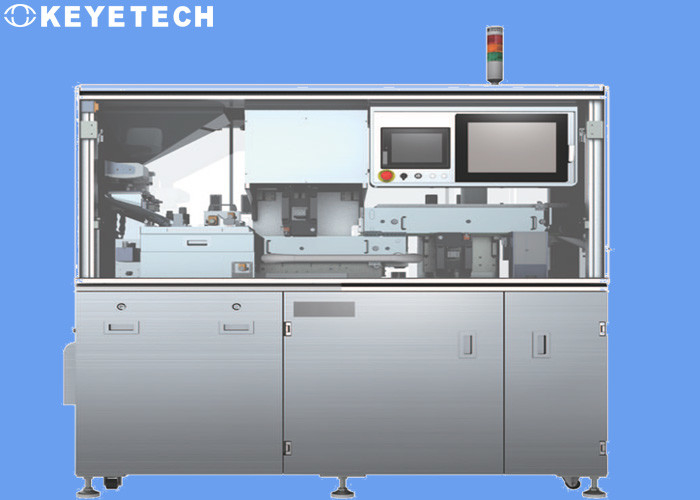

Full Automated Visual Inspection System For Rubber Stopper & Teats

System configurations

| Product |

Rubber Stopper & Teats |

| Speed |

450pcs/min |

| Components |

CCD industrial camera, high resolution lens |

|

|

| Precision |

0.01mm |

Weight |

900kg |

| Size |

1860x1360x2150mm |

Air compressed |

0.5-0.8Mpa |

| Current |

AC380V,50HZ |

Power |

2.5kw |

Inspection background

The quality of the rubber stopper directly affects the quality of the entire medical product. Therefore, it is necessary to collect the rubber stopper produced in a timely and comprehensive manner, and conduct a qualified inspection on it. Only the qualified products are allowed to enter the next link. Based on the special structure of the sheet rubber stopper, in the process of sampling the rubber stopper, multiple industrial cameras need to be arranged laterally to ensure 360° image capture without dead angle, and how to capture images in rapid motion, the camera is required to capture images. Therefore, the multi-dimensional adjustable camera bracket is particularly important. When the camera takes a picture of the rubber stopper, the edge of the glass turntable will reflect the light, the reflected light will affect the quality of the camera, and the photos taken by the camera will have bright spots, which will affect the detection results.

Inspection principle

The automatic rubber stopper visual inspection machine inspects the front, back, side and interior of the rubber stopper in all directions. It can detect multilateral shearing, tread, deformation, damage, stain, white spot, dirt, foreign body, hair, offset, surface wrinkle, bad sol, eccentricity, mixed shape, lack of glue, air bubble, etc. Defective products are eliminated, qualified products are automatically counted, and can be shunted to designated collection containers.

Features of system

- 360-degree accurate detection without blind spots

- Real-time storage of inspection data, dynamic display of inspection results, real-time images, running status, etc., real-time, accurate and non-destructive rejection of defective products

- Using the company's latest version 3.0 detection system, rapid modeling and variety management for different products, counting and statistics of the detection results, and automatic rejection of waste products.

- Equipment modular design, simple interface operation, stable system, simple maintenance and easy cleaning.

- Comply with GMP standard

Our advantages

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!