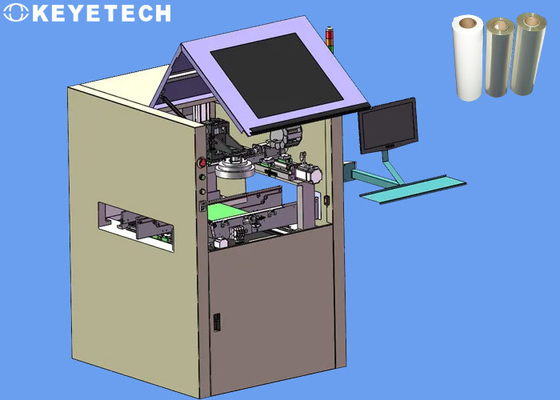

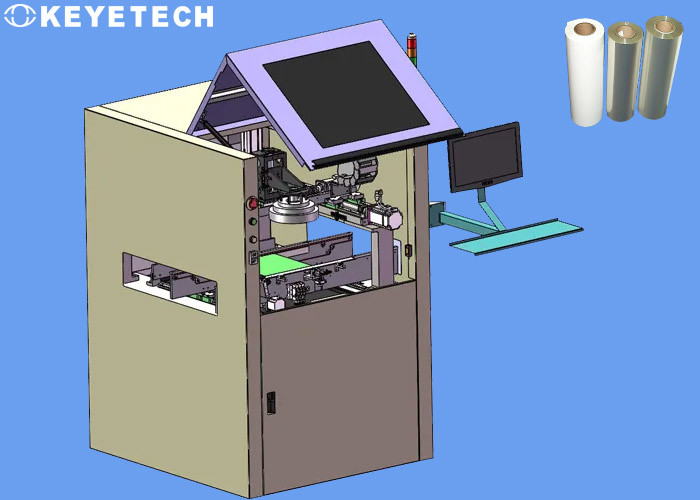

Visual Inspection System For PVC Film With HD Display Monitor Quality Sorting Machine

Features of system

| 1. Convenient operation: just click "Start", "Stop" to complete all operations; |

| 2. High stability: It can work continuously in the factory environment and can perform 24-hour uninterrupted testing; |

| 3. 100% web surface inspection: when a defect is found, an alarm can be issued according to the setting, prompting timely repair, and avoiding the production of a large number of defective products; |

| 4. High-precision detection: The solution can detect 100% of the defects above the required accuracy, and meet the customer's constantly improving product quality requirements; |

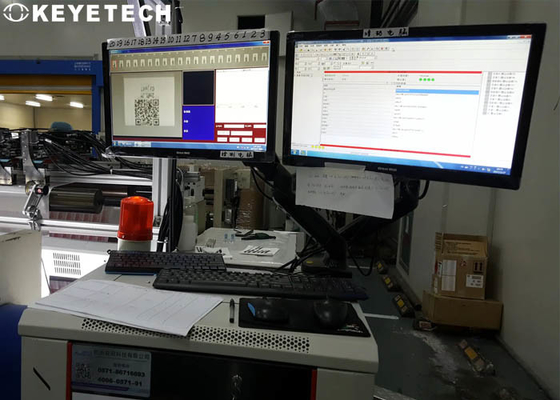

| 5. Software database management function: accurate quality statistics can be carried out for each roll of material produced, detailed defect records (size and position) and statistics provide convenience for production process and equipment status adjustment; offline analysis is used for subsequent cutting. And quality management, can effectively ensure product quality; |

| 6. System linkage: when the system detects a defect, it will give sound and light alarm, and other chain I/O outputs can also be added to the system; |

Inspection principle

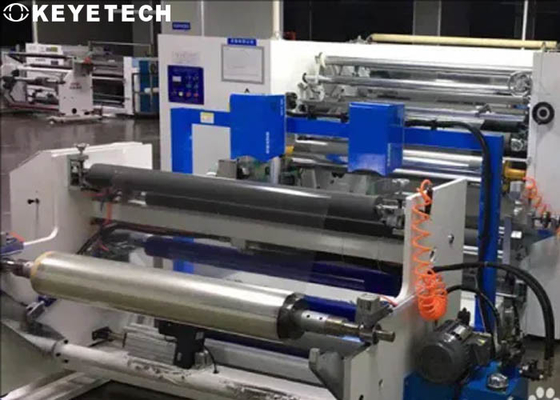

With the development of science and technology and the increase of demand, more and more film production enterprises require faster and higher production lines. However, relying on manual inspection has long been unable to meet the needs of production and high-speed film production lines, and it is easy to cause quality loss. Defect detection of film surface defects is mainly to detect various stains, impurities, mosquitoes and holes generated on the surface of the film during the production process. Human eyes are often unable to judge defects in a timely and accurate manner. The film surface defect detection system can perform high-speed and accurate online detection of surface defects generated in the production process, and display and identify all surface defects on the film surface.

KEYE TECH uses hardware equipment such as high-resolution line scan cameras, high-definition lenses and supporting line light sources, and cooperates with professional software technical strength to build a film surface defect detection system that meets the requirements according to the specific needs of customers. The system can accurately identify The defects in film production can be timely fed back to the defect information on the surface of the production line, and these defects are classified and processed, which greatly improves the production efficiency, saves costs, and better guarantees the quality of the film than manual defect detection.

Inspection details

The system can detect common surface defects such as dirty spots, streaks, damage, edge cracks, wrinkles, dark spots, bright spots, edge damage, black spots, hair, mosquitoes, etc. on the film, so the film surface inspection system becomes a high-speed film. Indispensable testing equipment in the production line.

When the production line is in normal production, the high-brightness LED linear condensing cold light source is irradiated on the surface of the production line by the principle of transmission (the detection principle of reflection is used for opaque film products). The system uses the film image collected by the camera to identify and process the defects through the image processing system software. Due to the obvious difference between the gray level of the defective image and the normal product, the system can find the defect, and at the same time, it can effectively judge, classify and process the defect.

Computer Vision and Machine Learning Aided Anomaly Detection

Traditional visual inspections have many limitations—the biggest being relatively slow responses. Once the machine detects an anomaly or defect, it can trigger automatic feedback that would have to be performed manually without artificial intelligence. In manufacturing, every second counts, and this can backfire. In the pharmaceutical industry, for example, a relatively small problem can affect an entire batch, causing huge losses.

Also quality assurance of consistency. With automated tools, all data about defects and anomalies stays in the system. The machine can draw conclusions from it, continuously improving its detection capabilities. Whereas in traditional defect and anomaly detection methods, the effectiveness of quality inspection can drop dramatically with any personnel changes and increase costs.

Our advantages

- 1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history

- Multi-orientation: 360 ° comprehensive inside and outside the samples

- High precision: detection accuracy can be high

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs

- Easy to operate: It is easy to operate and easy to maintain

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!