CCD Visual Inspection System Application of Plastic Industrial Automation

Advantages of machine vision

| 1)The system can check whether the design parameters and quality parameters are met. It can not only detect whether the products on the production line are qualified, but also find out the defects and their locations; |

| 2)Machine vision systems enable automatic positioning of products in production, ensuring they are ready for the next step; |

| 3)Machine vision uses the edges of objects to locate, identify, and measure them; |

| 4)After deep learning, machine vision can recognize non-standard characters and numbers even under challenging conditions. |

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Overview

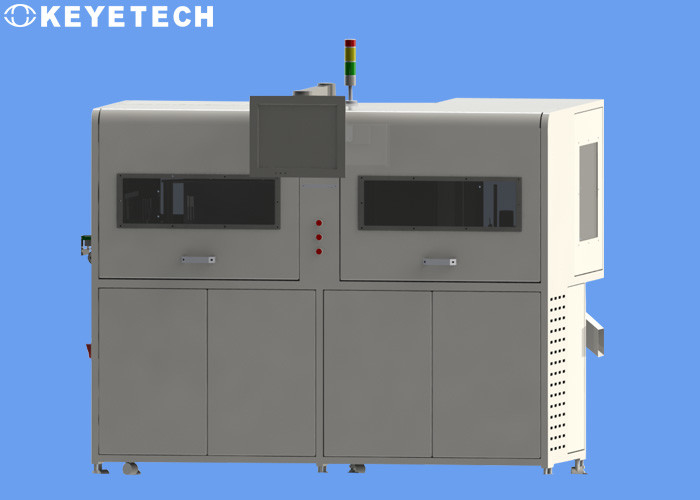

The design scheme uses high-pixel industrial cameras and high-performance strobe light sources to conduct all-round visual inspection for the appearance defects of products. The equipment can operate 24 hours a day. Products can be automatically rejected online.

The whole set of vision machines includes mechanical parts, visual electronic hardware and vision system software. The entrance and exit of the inspection machine can be integrated with the customer's on-site conveyor line, and can be connected with upstream and downstream production equipment according to the specific production needs of the customer's site.

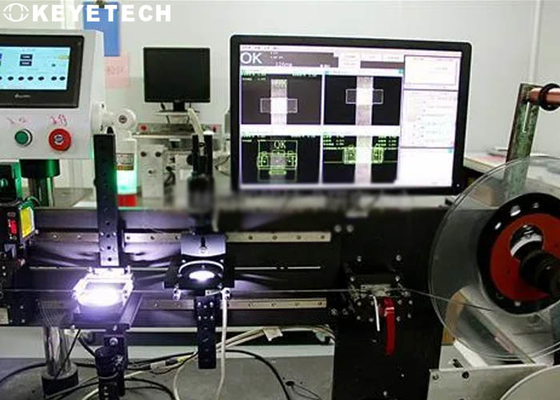

Software Function

- Enabling and disabling the system detection function

- Detection index parameters and accuracy adjustment

- Template sampling and saving, storage and retrieval of sample information

- Camera screen calibration function

- Real time production information display of the system (qualification rate, total output, speed, etc.), browsing of historical production information, export and storage functions

- Manage permissions based on login account (example, disabling parameter adjustment for general operation users)

- Operation and adjustment of the mechanical part of the system (If the transmission device is turned on, adjust the alarm signal)

Importance of machine vision

In recent years, machine vision has been one of the main drivers of industrial automation. It can help automate factory processes by collecting and intelligently responding to patterns in visual data. From products to people to processes, the smart factory of the future will use machine vision and data analysis to fully control factory operations and ultimately achieve better business decisions. For example, applications such as remote monitoring and edge analytics will provide the insights needed for predictive maintenance, reducing maintenance costs while reducing machine downtime.

Advances in image sensors, vision processors, and a wider range of hardware and software applications provide more options for computational intensity and power consumption, enabling solutions that meet end-user needs in specific industries.

When incorporated into deep learning, a form of artificial intelligence, machine vision systems are now able to perform vision tasks more accurately than the human eye. New machine vision technology solves problems that machines couldn't before -- for example, recognizing characters in low-light conditions and on curved surfaces. They can also handle high-resolution images and high-line-speed defect inspection.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!