Plastic Package Shower Gel Inspection Machine For Bottle Lip Body And Bottom

Shower Gel Inspection Machine For Bottle

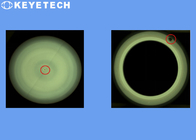

Detection Principle

(1)The transmission part is the core of the system, bearing all the transmission devices and electronic hardware (industrial camera, light source, industrial computer, touch screen, electrical box, etc.). The conveyor belt adopts vacuum adsorption belt to adsorb and fix the sample on the surface of the belt without sliding, so that the photography is accurate.

(2)Transmitted the shooting high-pixel sample image to image processing software by industrial camera, detecting and

determining a good product and defective product via AI manually intelligent algorithm.

(3)AI artificial intelligence algorithm to determine the pros and cons of products, to achieve automated production lines

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Testing Standards

| Model.No |

Camera |

Detection range |

Test content |

Error |

Accuracy |

Speed |

Remark |

| KVIS-T-C-C06 |

1set |

bottle shoulder |

black spot,

impurity

|

>=0.5mm |

99.5% |

100-120/min |

All other foreign bodies are treated as black spots |

| 1set |

bottle lip |

flash |

|

black spot,

impurity

|

| deformation |

| 4set |

side printing

surface

|

missing print |

the font to disappear |

100% |

| blur |

>=0.5mm |

99% |

|

black spot,

impurity

|

99.5% |

- Automatically the system checks whether functions are enabled or disabled

- Buy a ticket to detect indicator parameters and adjust the accuracy.

- Virtual Gateway A template samples and saves, storing and calling the detection information of a sample.

- Functions to adjust the camera's picture

- System features real-time production information (pass rate, total output, speed, etc.) display, browsing, exporting and storing historical production information.

- According to the login account, users can log in to the system according to their rights management.

- Buy a ticket to operate and tune the mechanical parts of your system (e.g. air valve ejection time, camera trigger time).

- Party A asks for additional functions to be added.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Our Advantages

- AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training.

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history.

- Multi-orientation: 360 degree comprehensive inside and outside the bottle without dead corners for medical packaging bottle caps, bottle mouths, bottle bottoms.

- High precision: detection accuracy can reach 99.5%.

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs.

- Easy to operate: It is easy to operate and easy to maintain.

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Anhui Keye Intelligent Technology Co.,Ltd

Address:168 Tangkou Road,Taohua Industrial Park,Hefei,Anhui

Tel:+86 186 5518 0887(James)/+86 173 5515 4206(Amy)

Email:clerk-zyl@keyetech.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!