Paper Coffee Lid Surface Detection AI Vision Inspection System Remote Access Support

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Theory

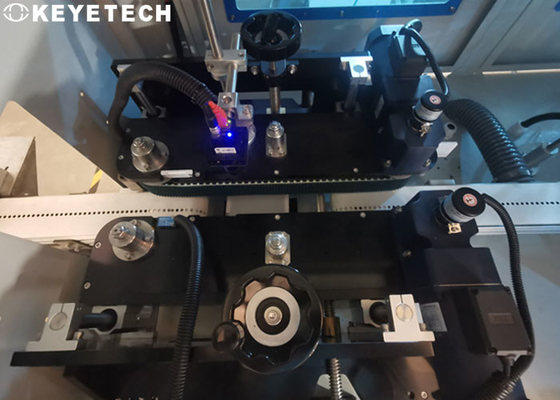

The product is stably and orderly transmitted to a specific workstation, and the high pixel sample images captured are transmitted to image processing software through customized LED light sources and HD industrial cameras. Based on big data, AI algorithms are analyzed and compared, and the system automatically determines defective and good products. The corresponding pneumatic components are controlled to eliminate defective products online, and the good products will be transported to the next station.

Camera Staions

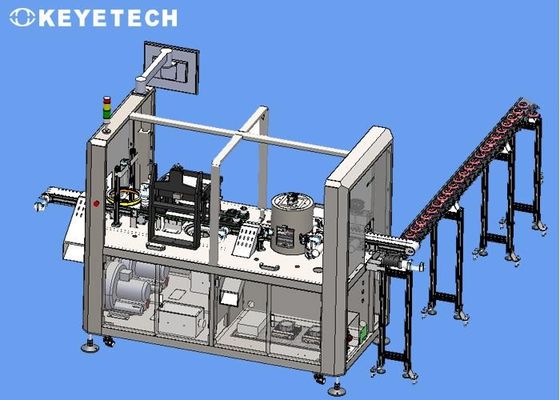

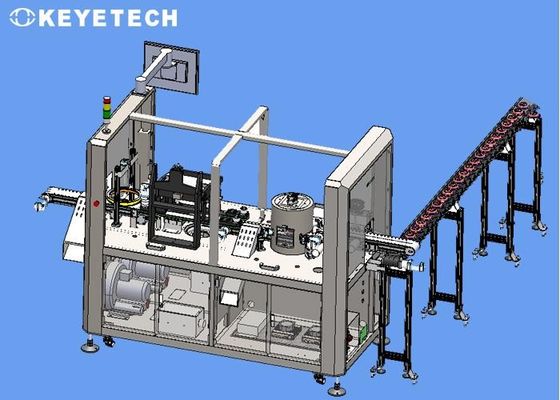

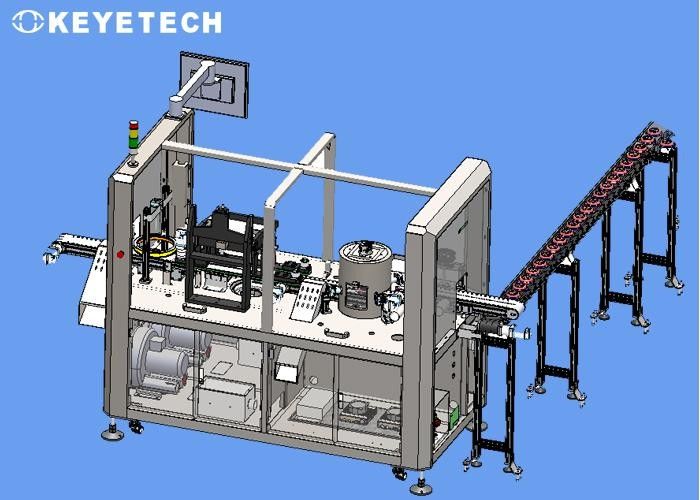

The overall equipment integrates mechanical mechanisms, visual optical hardware and detection system software, as well as defective product removal and counting devices. The normal detection speed is 200 pcs/min to ensure that products enter the detection station in sequence. Process of the inspection system:

The overall inspection equipment is equipped with 7 sets of high pixel industrial cameras to comprehensively detect the appearance defects of the product. After collecting sample images, the system compares and analyzes them with standardized templates through image processing software to determine whether they are good or bad. Defective products are automatically removed online, and counting function can be achieved after finished product inspection.

Operation Parameters

| Power |

5-7Kw |

Voltage/Current |

380 V 50 HZ |

| Noise |

<70dB |

Compressed air |

0.5~0.8MPa |

| Ambient Temperature |

-20℃ ~ 60℃ |

Ambient Humidity |

Less than 50% |

| System Language |

English/Russian/Ukrainian |

Mechanical Structure |

Carbon Steel |

| Total Weight |

About 500kg |

Dimension |

Reference drawings

|

Software Function

- Enabling and disabling the system detection function

- Detection index parameters and accuracy adjustment

- Template sampling and saving, storage and retrieval of sample information

- Camera screen calibration function

- Real time production information display of the system (qualification rate, total output, speed, etc.), browsing of historical production information, export and storage functions

- Manage permissions based on login account (example, disabling parameter adjustment for general operation users)

- Operation and adjustment of the mechanical part of the system (If the transmission device is turned on, adjust the alarm signal)

Cooperation Partners

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!