Inspection Object

The society is becoming more and more dynamic. The existence of coffee lids facilitates most people's travel to work. With the development of time, more and more logos are printed on coffee lids. In order to strengthen brand benefits, businesses Highlight the brand's influence, continue to innovate the design of the coffee cover, and then deliver it to the factory for processing. Therefore, the appearance inspection of coffee lids is an important link that many manufacturers must take into account. Due to the production process and material problems, coffee lids may have black spots, folds, characters and hole sizes. Therefore, many The manufacturer breaks through the shackles of traditional inspection and introduces the latest AI vision inspection equipment in order to speed up the production process and increase the production speed.

In response to the above problems, Keye Technology has designed a complete inspection system for coffee caps, taking the appearance defect inspection of the finished coffee cap with a diameter of 80mm/a coffee cap with a diameter of 90mm (bottle cap series) as an example:

Inspection Principle

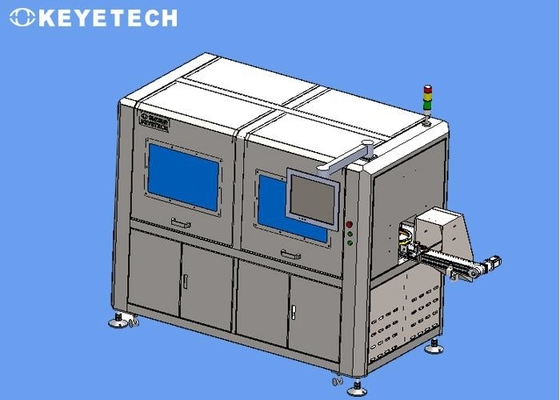

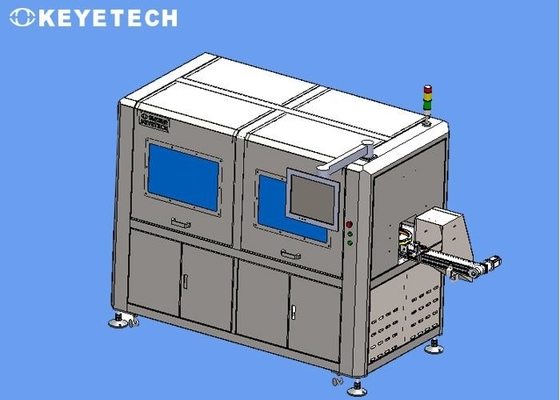

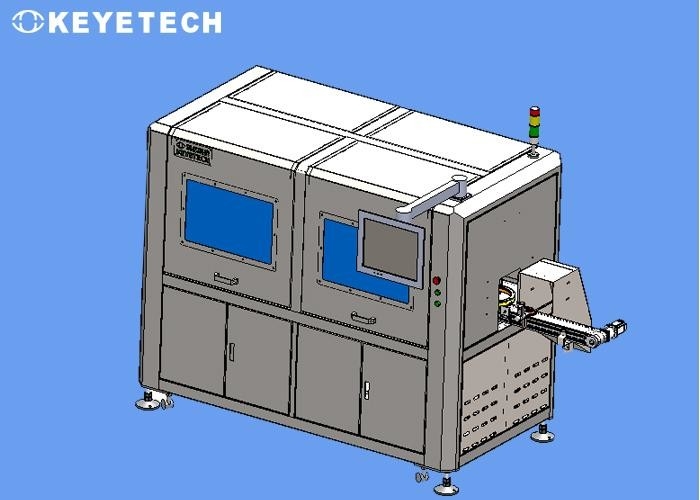

The whole system integrates mechanical mechanisms, visual optical hardware and detection system software, defective product rejection and counting devices. The normal detection speed is 300 pieces per minute. The entrance and exit of the detection machine can be integrated with the customer’s on-site conveyor line. The equipment can be realized. It runs 7*24 hours a day, which greatly improves production efficiency.

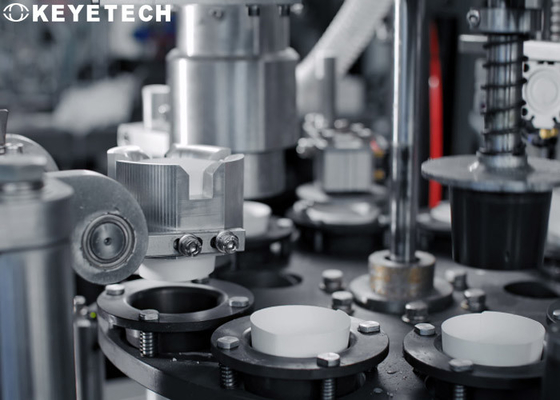

The front-end capping equipment separates the finished coffee caps in a stable and orderly manner and transmits them to the inspection station through the conveying equipment. The inspection station collects high-definition images and transmits them to the image processing software in the industrial computer. After comparing with the standardized samples, the defective products and the good products can be distinguished. And control the corresponding pneumatic components to eliminate defective products.

The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

Inspection Details

Based on customer requirements, after a long period of testing and improvement, our company can basically share a device for products with diameters of 80 and 90, but on-site staff need to make some adjustments to the equipment when changing production. Our design plan is as follows:

- Two diameter coffee lids: for the detection of appearance defects such as the convex surface, concave surface, black dots of the peripheral surface, folding, characters and the size of the two holes on the convex surface of the coffee cover, the equipment needs to be equipped with 6 sets of industrial camera systems with a detection speed of 300 /minute.

- The system can work 7*24 hours a day. The entrance of the equipment is integrated with the equipped conveyor line, and the exit of the equipment is integrated with the infrared heating + ultraviolet sterilization equipment. The unqualified products can be automatically rejected online.

Inspection Standard

| Model |

Number of camera

|

Inspection scope

|

Inspection content

|

Detection precision

|

Accuracy

|

Capacity |

|

KVIS-C-

SC06

(Diameter

80mm)

|

1 set |

Convex area

|

Black spot, print blurred, Nozzle size

|

≥0.2mm |

99.9% |

300Pcs/mins

|

| 1 set |

Concave area

|

Black spot |

≥0.2mm |

99.9% |

| 4 sets |

Side area

|

Black spot |

≥0.2mm |

99.9% |

| Fold |

Yes/no

|

99.9% |

|

KVIS-C-

SC06

(Diameter

90mm)

|

1 set |

Convex area

|

Black spot, print blurred, Nozzle size

|

≥0.2mm |

99.9% |

300Pcs/mins

|

| 1 set |

Concave area

|

Black spot |

≥0.2mm |

99.9% |

| 4 sets |

Side area

|

Black spot |

≥0.2mm |

99.9% |

| Fold |

Yes/no

|

99.9% |

NOTES: The defective product will be take out in the system

- Ø The counting function can be realized after the finished product is tested, and the counting accuracy rate is 100%.

- Ø The testing equipment needs to be regularly maintained and cleaned during use (such as conveyor belt cleaning, camera cleaning, etc.). The testing equipment itself will not cause secondary pollution sources (such as debris, fine foam, etc.) to the tested samples.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!