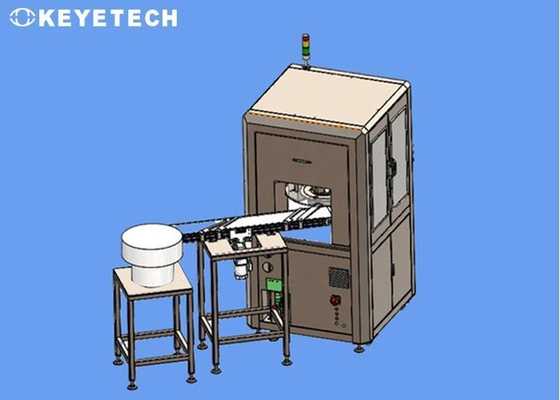

Small Diameter Vision Inspection Machine for Rubber Stopper Components

Product background

Anhui Keye Intelligent Technology Co., Ltd. based on a strong scientific research team, supplemented by years of accumulated experience in the visual appearance inspection industry. According to different application industries, KEYE TECH has designed a variety of instruments suitable for different industry needs. Integrity, focus, innovation, and excellence, KEYE TECH is committed to becoming the world's top AI visual inspection product provider, providing customers with leading technology, cost-effective products and efficient services.

Inspection principle

The materials are arranged by vibrating plate, Linear vibration and non-destructive conveying, and the capacitance is stably and orderly transferred to the specific inspection station, and then the high-pixel sample image captured by the industrial camera is transferred to the image processing software. After the system analyzes and processes, it judges good and defective products, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products.

The inspection machine adopts 17 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out omni-directional visual inspections for product appearance defects. The inspection speed is 100-400 pieces/min. The equipment can realize 7*24 hours of all-weather operation, and it can be online automatically. Eliminate substandard products.

The whole set of inspection equipment includes mechanical, visual electronic hardware and inspection system software. The entrance and exit of the equipment are reserved for docking positions to facilitate on-site operations.

| Name |

Rubber part sorting machine |

Model |

KY-RP |

|

Dimension(mm)

L*W*H

|

As actul design |

Voltage |

Local standard |

| Power |

4KW-7KW |

Pressure |

0.4-0.7Mpa |

| Conveying method |

Vibrating plate feeding |

Inspection method |

Online real-time inspetection |

| Camera type |

High-speed industrial camera |

Number of cameras |

14 sets of camera |

| Algorithm |

Deep learning |

Compatible product size |

Φ8-10,12,13 |

| Speed |

100~400/min |

Rejection method |

Pneumatic |

Software Function

- Enabling and disabling the system detection function

- Detection index parameters and accuracy adjustment

- Template sampling and saving, storage and retrieval of sample information

- Camera screen calibration function

- Real time production information display of the system (qualification rate, total output, speed, etc.), browsing of historical production information, export and storage functions

- Manage permissions based on login account (example, disabling parameter adjustment for general operation users)

- Operation and adjustment of the mechanical part of the system (If the transmission device is turned on, adjust the alarm signal)

Cooperation Partners

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Delivery Time

The production cycle of the whole machine is expected to take 60 days. If additional inspection requirements are added or more adjustment needed, the time will be appropriately extended accordingly. After the equipment arrives at the customer's site, our company arranges after-sales personnel to complete installation and adjustment at the customer's site.

After Sales Service

- The seller should complete the creation and debugging of the product basic algorithm model before the equipment is shipped, also provide remote assistance after the equipment arrives at the customer site; and provide buyer with the factory data and operation manual of equipment.

- Daily operation and maintenance services: Our company provides free remote operation and maintenance online services. If you need to upgrade inspection algorithm, provide operational assistance, etc.

- Our company have regular offline training plan every year, so domestic and foreign clients can send their engineers to participate (at their own expense). Those who pass the exam can obtain an industry functional skills certificate.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!