In the process of changing PET from material to bottle, there is a very critical process, namely bottle blowing. The bottle blowing machine transforms each preform into various shapes of packaging bottles. The bottle blowing machine drives the bottle preform by high-speed rotation to achieve molding. During the molding process, the quality of the bottle mouth is particularly critical. If there are defects such as damage, cuts or even deformation, the subsequent filling and capping will lead to poor sealing of the bottle, which not only causes a lot of waste, but also causes the internal liquid to deteriorate, so it is particularly important to detect the defects of the bottle mouth.

System overview

The system transports the ice tea packaging bottle samples to the predetermined station in a stable and orderly manner, and then transmits the captured sample image to the image processing software through the high-pixel industrial camera, compares with the standardized sample and distinguishes the defective product and the good product, and remove defective products through compressed air. The false detection rate is 0.03.

The software sets the comparison standard for the samples, operators can control the comparison precision and choose the precision standard that best suits themselves, thereby controlling the defect rate.

The detection performance is as follows:

-Detection of the bottom of the outside of the bottle (1 set of camera): detect whether there are holes, black spots, stains, mark label missing and other defects.

-Detection of the bottom of the inside of the bottle (1 set of camera): detect whether there are black spots, stains, foreign objects and other defects.

-Bottle mouth detection (1 set of camera): detect whether there are deformation, lack of material, overlap, burrs, black spots, stains, and other defects, to ensure that the bottle mouth is intact.

-Bottle body detection (8 sets of camera): inspect all appearances for defects such as black spots, stains, impurities and damage, holes, and serious uneven thickness. Including whether the bottle packaging is intact, missing labels, missing labels, curling, stains.

-Detection speed: 200-220pcs/min

-Detection accuracy: 0.2mm

-Precision: 99%

-Detection range: The entire bottle, including the inner and outer bottoms, and the bottle mouth.

System composition

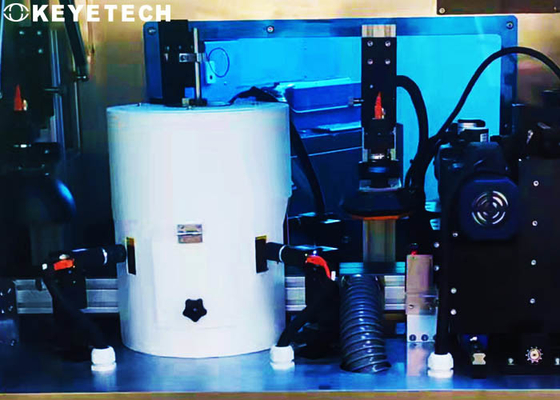

1. Mechanical part

The customer should inform the height and size of the on-site equipment in advance to facilitate the docking of the equipment conveyor belt inlet and outlet with the customer’s on-site conveyor line. The transmission part is the core component of the system, which carries all the transmission devices and electronic hardware (industrial cameras, light sources, industrial computers, touch screens, electrical cabinet, etc.) . The transmission part adopts advanced separation technology and vacuum adsorption technology to ensure that the electronic system captures images quickly and accurately. After the detection is over, the equipment adds the function of counting the detection products. The counting accuracy is 100%.

2.Software part

The software is the general control platform of the equipment, and the specific functions are as follows:

-Open and close the system detection function

-Adjustment of detection index parameters and accuracy.

-Template sampling and storage, sample detection information save and recall.

-Camera image calibration function

-The system displays real-time production information (qualification rate, total production, speed, etc.), historical production information browsing, export and save functions.

-Permission management based on the login account (such as general operation users disable parameter adjustment permissions)

-Operation and adjustment of the mechanical part of the system

(Such as open the transmission device, the adjustment of the air valve blow time, and the adjustment of the alarm signal)

-Additional functions that Party A needs to add

3. Hardware part

This detection system uses 11 high-pixel industrial cameras and supporting industrial lenses, with 3 sets of high-brightness stroboscopic light sources, which can truly achieve 360-degree detection of the bottle body.

The overall logic control of the system is realized by a single-chip microcomputer, and the specific functions include:

-Trigger the camera to take pictures

-Trigger light source strobe

-Trigger solenoid ejector blow to eliminate waste

-Control the belt speed

-Emergency handling in the case of material jams in system

-Trigger the warning light signal

| System operating parameters |

| Dimensions |

2.4×1.0×1.8(m) |

Power and frequency |

220V 20A 50HZ |

| Total power |

3.5kw |

Air pressure |

0.5~0.8MPa Purify and oil-free |

| Working temperature |

-20℃ ~ 60℃ |

Working humidity |

Below 50% relative humidity |

| Sample diameter |

10mm-120mm |

Sample height |

20mm-200mm |

Machining process

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!