High Precision CRC CT Pharmaceutical Cap Online Visual Inspection Machine

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Principle

With the reform of the medical system in various countries, the packaging of medicines is disorderly, and the backward situation will undergo a fundamental change. At present, many countries are continuously introducing and updating pharmaceutical packaging machinery and materials, and the pharmaceutical packaging industry will present a brand new situation.

Testing Standards

| Model |

Number of camera |

Inspection scope |

Inspection content |

Detection precision |

Accuracy |

Capacity |

Remark |

| KVIS-CC06 |

4sets |

Outside surface |

Black spot≥0.2mm |

99.8% |

99% |

500pcs/min |

|

| 0.5mm<Flash, injection incomplete≤1mm |

99% |

| 1set |

Concave surface |

0.5m<Injection incomplete≤1mm |

99.8% |

| Black spot≥0.2mm |

99.8% |

| 2mm<Transformation |

99% |

| 1set |

Trademark surface |

Black spot≥0.2mm |

99.8% |

| Note: The system equipped with 2 million pixel-level industrial cameras. |

Equipment Overviews

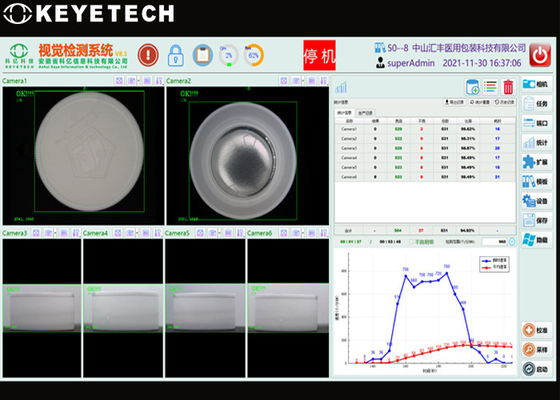

1.Six cameras detect many kinds of detects on the inside, outside and surface of the bottle cap 360 degrees without

dead edge angle and blind area.

2.Real time display of sample image,running status,real-time statistics of detection results and defect classification information

of detective products.

3.According to the actual needs of the production site,flexibly change the detection function and accuracy.

4.Save each sample feature to the model database and switch sample detection with one click backup restore system data.

5.The contact part between the equipment and the sample is made of medical materials,which is easy use and maintain.

6.The detection function is highly modular,and it can flexibly increase or decrease the detection function according needs.

Many of our products have been adopted by many domestic pharmaceutical enterprises and related manufacturers, and become an indispensable automatic testing equipment for drug quality testing, which not only greatly improves the testing capacity, reduces labor costs, but also improves product quality management to a new height, which has been widely recognized and praised by customers.

Cooperation Partners

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G, Unilever, ALPLA, Shriji Polymer, Berry Global, Aptar, LAMIPAK, TPAC, PACT Group, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!