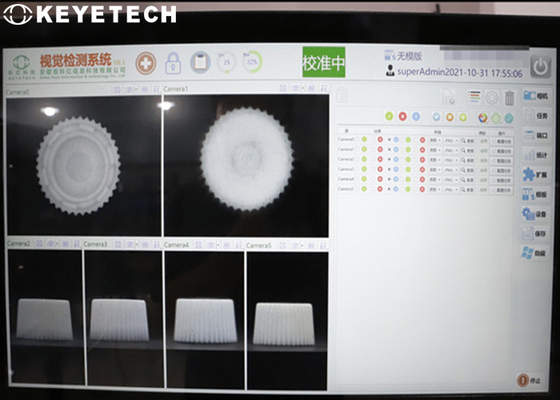

Full Automatic Visual Inspection System for Irregular Cap Closures

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Principle

Pour the bottle cap with a diameter of 5`6mm into the cap arrange equipment through the conveying line transport it stably and orderly through the photographing area of the industrial camera, and transfer the captured high-pixel sample image to the image processing software for comparison and analysis with the standardized model Afterwards, it is determined whether the concave surface of the bottle cap, the trademark surface, and the side surface are defective, and the corresponding pneumatic components are controlled to remove the defective products, and finally the qualified products are collected. Our design plan is equipped with 6 sets industrial cameras, one set cap arrange equipment, to conduct a full range of defect detection on the concave surface, trademark surface and side of the bottle cap. The normal detection speed is 300-800 pcs/min.

The standards are as follows:

| Model |

Number of camera

|

Inspection scope

|

Inspection content

|

Detection precision

|

Accuracy

|

Capacity |

| KY-PC |

4sets |

Outside surface

|

Black spot≥0.2mm |

99.8% |

99% |

300-800

pcs/min

|

| 0.5mm<Flash, injection incomplete≤1mm |

99% |

| 1set |

Concave surface

|

0.5m<Injection incomplete≤1mm |

99.8% |

| Black spot≥0.2mm |

99.8% |

| 2mm<Transformation |

99% |

| 1set |

Trademark surface

|

Black spot≥0.2mm |

99.8% |

Function of the inspection software

1.Enabling and disabling the system detection function.

2.Adjustment of detection index parameters and accuracy.

3.Template sampling and storage, sample detection information storage and recall.

4.Camera screen calibration function.

5.The system displays real-time production information (qualification rate, total output, speed, etc.), browsing, exporting and storing historical production information.

6.Permission management based on the login account (such as general operation users disable parameter adjustment permissions).

7.Operation and adjustment of the mechanical part of the system.(Such as the transmission device is opened, the air valve injection time is adjusted, and the alarm signal is adjusted.

Machining Process

|

1. Preparation of production and technology, such as design and manufacture of process design and special process equipment, preparation of production plans and preparation of production materials

2. Blank manufacturing such as casting, forging and stamping

3. Machining of parts, cutting, heat treatment and surface treatment

4. Assembly of products such as final assembly, partial assembly, debugging inspection and painting

5. Production services such as supply, transportation and storage of raw materials, purchased parts and tools etc.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!