Alaska Cap Online Vision Inspection System High Speed 1000pcs per min

Equipment Overview

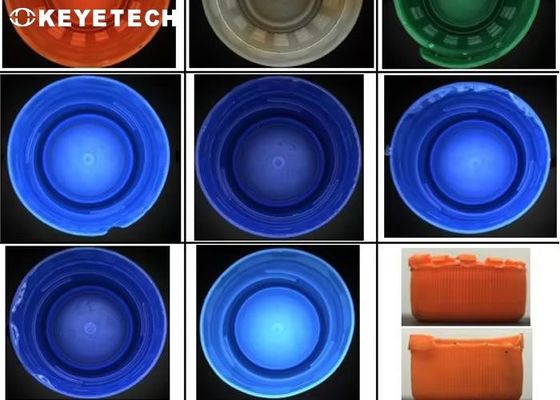

We adopt 6 sets of high pixel industrial cameras and high-performance LED strobe light sources to conduct comprehensive defect inspection on the appearance of products. The entire set of vision inspection equipment includes mechanical transmission part, optical imaging system, visual electronic hardware, and detection system software. The entire equipment can be independently placed on the customer's site and the maximum detection speed can reach 400~1000pcs/min, the unqualified products can be automatically rejected online and good products can be counted and packed if needed.

Inspection Theory

The product is stably and orderly transmitted to the KEYE vision inspection machine, and the high pixel sample images captured are transmitted to image processing software through customized LED light sources and HD industrial cameras. Based on big data, AI algorithms are analyzed and compared, and the system automatically determines defective and good products. The corresponding pneumatic components are controlled to eliminate defective products online, and the good products are counted and boxed to complete product inspection.

** The process of camera inspection system:

| Camera Station |

Inspection Content |

| Station1 |

CAM1 used to check cap flat side defect issue |

| Station2 |

CAM2 used to check cap concave side defect issue |

| Station3 |

CAM3/4/5/6 used to check cap outer sidewall defect issue |

Inspection Detail

Based on customer needs, taking into account system complexity and feasibility, the requirements and indicators for cap appearance inspection are as follows:

|

Camera

Q’ty

|

Inspection Position |

Defect Types |

Accuracy |

Speed |

| 6pcs |

Flat side |

Black spot, flash, broken, ring damaged, deformation, ovality issue, short filling, etc. |

>99% |

400-1000 pcs/min |

| Concave |

| Outer side |

Software Function

Ø Enabling and disabling the system detection function

Ø Detection index parameters and accuracy adjustment

Ø Template sampling and saving, storage and retrieval of sample information

Ø Camera screen calibration function

Ø Real time production information display of the system (qualification rate, total output, speed, etc.), browsing of historical production information, export and storage functions

Ø Manage permissions based on login account (example, disabling parameter adjustment for general operation users)

Ø Operation and adjustment of the mechanical part of the system (If the transmission device is turned on, adjust the alarm signal)

Company Profile

KEYE TECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Through the project practice in the fields of packaging containers, 3C, medicine, textile, food, etc., the KVS-AI software and hardware platform has been created, so that AI technology can be transformed into real productivity. We provide visual imaging, algorithm computing power and automatic control AI system solutions for various sub-industries.

Machine Parameters

| Model.No |

KY-PC-06W |

Inspect speed |

400-1000 pcs/min |

| Size |

1850*1260*1820mm |

Weight |

300kg |

| Voltage |

Local standard |

Current |

5kw-7kw |

| Ambient temperature |

10~30℃ |

Environment humidity |

Relative temperature≤85% |

After-sale Service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!