Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Principle

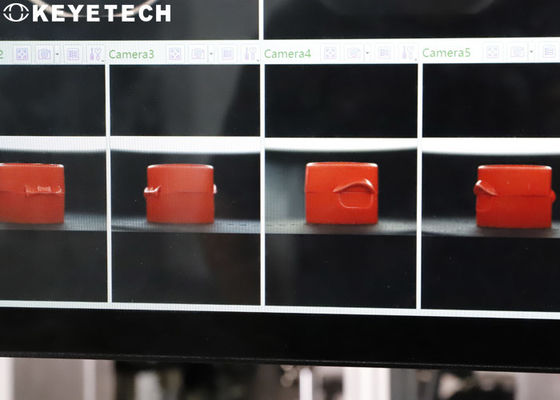

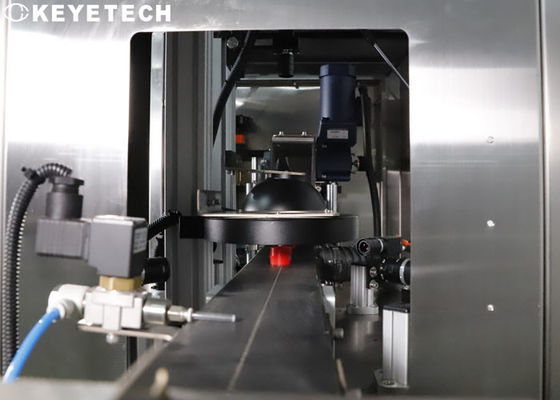

The design scheme uses high-pixel industrial cameras and high-performance strobe light sources to conduct all-round visual inspection for the appearance defects of products. The inspection speed is 300-1000 pcs/min, and the equipment can operate 24 hours a day. Products can be automatically rejected online.

The whole set of vision machines includes mechanical parts, visual electronic hardware and vision system software. The entrance and exit of the inspection machine can be integrated with the customer's on-site conveyor line, and can be connected with upstream and downstream production equipment according to the specific production needs of the customer's site.

Testing details

The inspection system equipped with 11 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to conduct a full range of visual inspections for the appearance of bottle cap products. The inspection speed can reach 400 pieces per minute, and the machine can achieve 7*24 hours. The defected caps can be automatically rejected .

The whole inspection system includes material sorting equipment, mechanical structure, visual electronic hardware and testing system software, which can be independently arranged on the customer site, and can be equipped with dust removal, disinfection and other production line equipment according to the specific production needs of the customer on the site.

Hardware:

- Camera: We use our own developed camera (the chip is from Japan), which has clearer image recognition and is more compatible with our own software.

- Light source: We have a dedicated optical team to develop various light sources to adapt to the optical scene requirements of different industrial scenes.

- Embedded computer: The KEYE team independently developed the embedded computer NPU computing box, which replaced the traditional PLC industrial computer; it is not afraid of sudden power outages and high temperature scenes, and can better adapt to the high temperature environment.

Software:

- Algorithm: We use the latest AI deep learning algorithm. Most products only need a small amount of sample learning to complete a new product model; the machine can continuously learn some defects and good samples like the human brain, making the detection effect better and better.

- Software: The latest KEYE V16.0 software can realize a variety of data statistics and human-computer interaction functions, and the touch screen operation is simpler.

- KEYE cloud platform: The AI cloud platform can create its own cloud platform account for each customer, and the pictures of each training operation will be saved in its own account; even if the algorithm is lost due to software algorithms or other problems, all previous data can be retrieved through an independent cloud platform account. (KEYE team has technicians who regularly maintain this platform).

- After-sales service: Provide long-term remote service, customers only need to keep the device in good network connection.

Cooperation Partners

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!