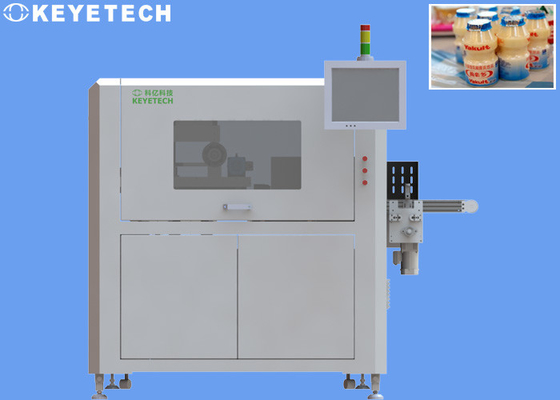

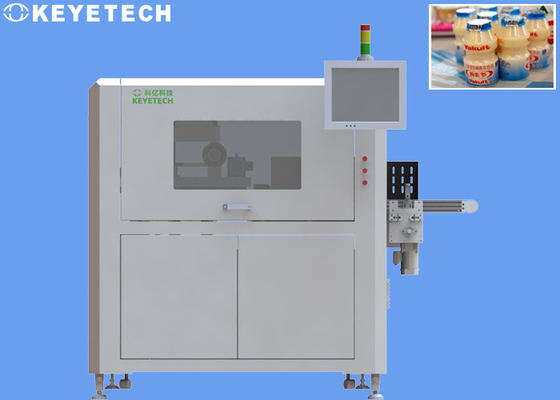

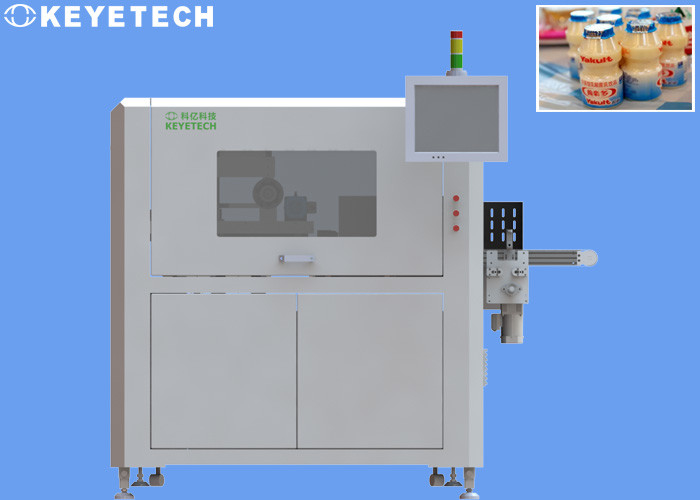

Milk Beverage Bottle Visual Inspection System for Surface Defects Detection

Inspection standards

| Model |

Camera number |

Detection range |

Detection content |

Accuracy |

Precision |

Speed |

| KY-PB-06D |

1set |

Bottle mouth |

Black spots, stains, overlap, burrs, lack of material, etc. |

≥0.5mm |

Qualified product 99.5% |

100-300 pcs/min |

| False detection is less than 0.5% |

| 1set |

Bottom of the bottle |

Black spots, stains,foreign material, etc. |

≥0.5mm |

Qualified product 99.5% |

| False detection is less than 0.5% |

| 4-8 set |

Bottle out sidewall |

Black spots, stains,missing, etc. |

≥0.5mm |

Qualified product 99.5% |

| False detection is less than 0.5% |

Detection principle

We adopt 6 sets of high pixel industrial cameras and high-performance LED strobe light sources to conduct comprehensive defect inspection on the appearance of products. The entire set of detection equipment includes a sample material handling system, mechanical transmission part, optical imaging system, visual electronic hardware, and detection system software. The entire equipment can be independently placed on the customer's site, The maximum detection speed can reach 100-300pcs/min, the unqualified products can be automatically rejected online and good product can be counted and packed if needed.

Through the testing equipment, unqualified products can be detected in the production process in time, and the possible problems in the production line can be checked, which can also save labor and improve production efficiency. It is an indispensable link in the production of enterprises. Keyi Technology has the latest artificial intelligence equipment. After continuous tempering, learning, and upgrading of tens of thousands of samples, it has been able to accurately detect various packaging problems, and the detection accuracy rate is as high as 99%.

Inspection principle

Transfer the bottle products to a specific station in a stable and orderly manner, and then transmit the captured high-pixel sample image to the image processing software through an industrial camera. Defective products are eliminated, and qualified products are finally collected.

The software will open the sample comparison standard, and the production personnel at the customer site can control the comparison accuracy and select the most suitable accuracy standard for their own production conditions, thereby controlling the defect rate. Greatly reduce costs.

Inspection details

Our design plan uses 11 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out comprehensive detection for bottle mouth, bottle bottom and bottle body defects. The whole set of detection equipment includes mechanical parts, visual electronic hardware and detection systems. The software, the entrance and exit of the detection machine can be integrated with the conveyor line, the detection speed is 9600 pieces/hour, the equipment can realize 7*24 hours of operation, and the unqualified products can be automatically rejected.

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G,Unilever,ALPLA,C'estbon, Nongfu Spring, etc., and has won praise from many users.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!